Environmental Engineering Reference

In-Depth Information

and resources. The benefits of a zero waste policy are that it reduces operation costs,

increases profit and complies with environmental regulations. The CSC continuously

creates new technology to reduce waste or transfer it into useful resources through

continuous improvement in the manufacturing process, consistently moving towards

a zero waste system. With the improvements in technology and investment in the R

& D Department over the past two decades, CSC has accomplished its missions and

goals gradually.

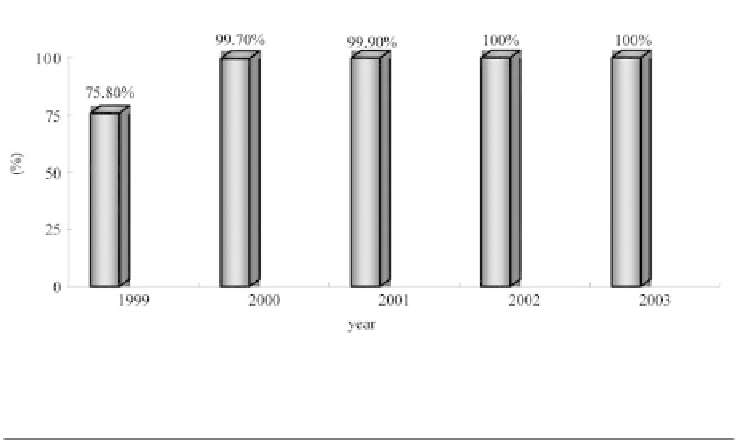

Its performance in reducing residues and recycling will be shown in the Table 4

and Figure 7.

Figure 7.

Percent of sludge recycled at CSC since 1999 [42].

Table 4.

By-products of process residues in 2004 [44].

Generation

(10,000 tons)

%oftotal

residues

Type of residue

Description

BF slag

By-products of BF after smelting or raw materials

303.9

49.0

BOF slag

By-products of the basic oxygen furnace (BOF) after refming of steel

128.2

20.6

De-S slag

By-products of the hot metal desulfurizing process

36.8

5.9

Dust

Particulates collected from de-dusting system

34.1

5.5

Sludge

Solid cakes or mud from wastewater treatment after condensing and

dehydrating

44.8

7.2

Mill scale

Rust of steel products or semi-products

29.4

4.7

Spent refractory

Used refractory from high temperature process

4.0

0.6

Civil refractory

Residual soil, concrete, etc.

19.8

3.2

Limestone cake

Filter cake from limestone washing water

5.0

0.8

Other

Waste oil, waste packaging materials, refuse, etc.

15.5

2.5

Total

621.5

100

Search WWH ::

Custom Search