Civil Engineering Reference

In-Depth Information

Reduction of energy

consumption in the building

industry

It is quite possible to reduce drastically the

amount of energy consumed in building. The

following steps could achieve a great deal:

Energy saving during the manufacturing

process

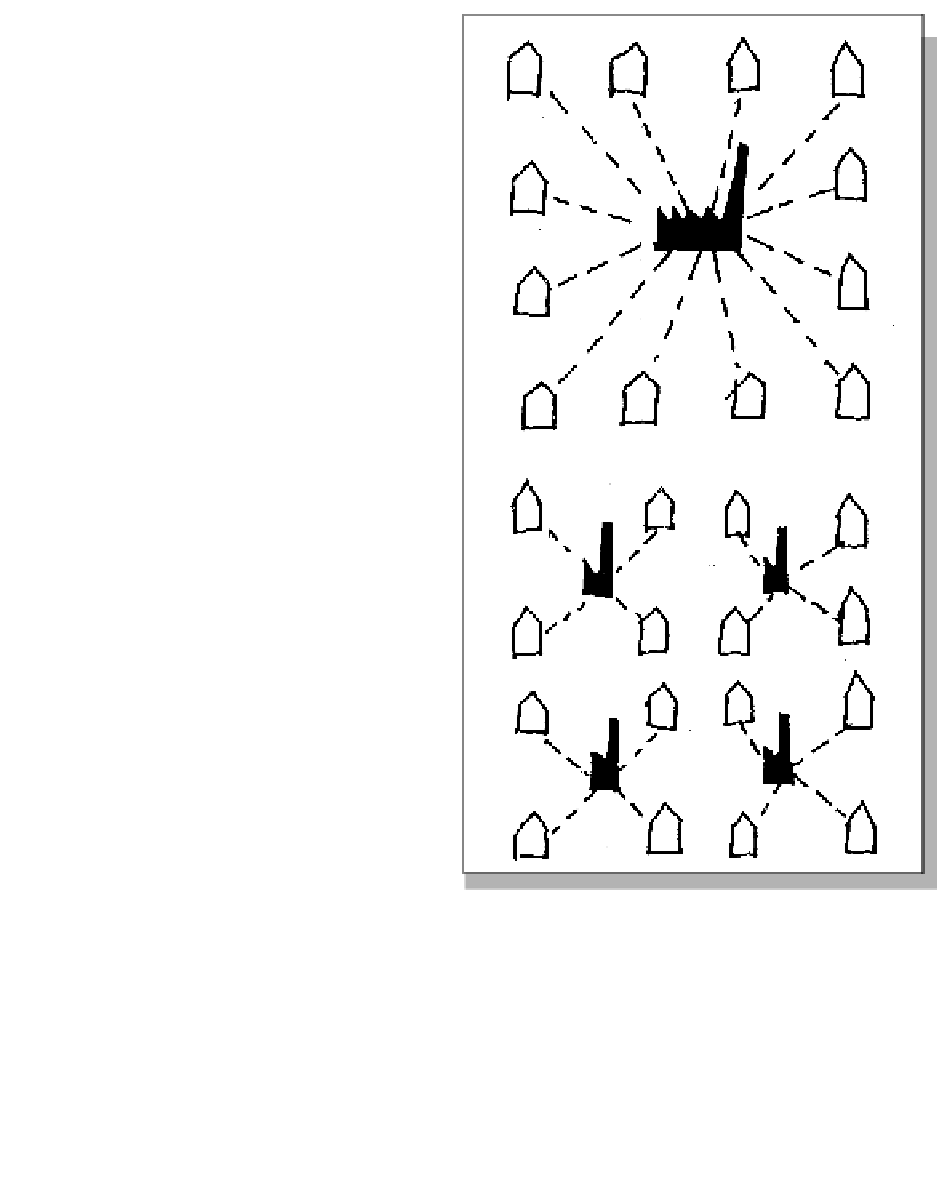

Decentralized production

This requires less transport and is especially

appropriate when local materials are being

processed (see Figure 1.6).

Use of highly efficient sources of energy

Electricity produced from oil, coal and

nuclear power achieves only 25-30 per cent

of the potential energy available. The degree

of efficiency is thereby 0.25-0.3, and the rest

is lost. Hydro-electricity has an efficiency

coefficient of 0.6, which is not particularly

impressive either. In many cases it would be

better to avoid electricity and use sources of

energy within production that use direct

mechanical or intensive heat energy - rota-

tional power is an example. The source of

energy must have a clear relationship with

the manufacturing process used. This princi-

ple can be determined in terms of levels of

energy quality (see Table 1.2).

Figure 1.6: Local industries create less need for transport.

Source: Plum 1977

Use of local sources of energy

The shorter the distance between the power

station and the user, the smaller the amount of energy lost in the network/distri-

bution line. Over larger distances the loss can be as great as 15 per cent. Small local

power stations have shown definite economical advantages over recent years.

Other energy saving changes

It is possible to reduce energy consumption in certain industrial processes by

using efficient heat recovery and improved production techniques. Cement