Civil Engineering Reference

In-Depth Information

critical being the lowest water-

proofing layer which prevents

water from entering the actual

roof structure. This was once

done using birch bark, but is

now achieved using bitumi-

nous products and plastic mem-

branes. A normal waterproofing

layer is built up in two layers

with a polyethylene membrane

of about 0.5 kg/m

2

on top of a

polyester-reinforced bitumi-

nous felt of about 2 kg/m

2

.

Polyvinyl chloride products are

also used. Bitumen-based glue

and mastic is used for laying

and jointing.

Turf roofs have dominated

building history in northern

Europe as long as can be

remembered. Resources have

been boundless and laying

methods relatively simple,

though labour-intensive. The

high thermal insulation offered

by turf roofing made it a strong

competitor against slate, tiles

and other materials that subse-

quently appeared on the mar-

ket. The thermal insulation

makes it common even in the tropics. There are houses in Tanzania which have

a 40 cm-thick layer of earth with grass on the roof.

Climate has little effect on a turf roof, wherever it is. In very exposed, windy

sites along the coast there are, however, stories of roofs of this type being blown

off. With the demand for even better insulation and less labour-intensive methods

the turf roof became less competitive. Today it is mainly relegated to

Scandinavian summer cottages in the mountains. But during the last 10 years

there has been a renewed interest in this roofing material, because of the ability of

green plants to reduce air pollution noticeably by binding dust, breaking down

gases and producing oxygen. It has been discovered that if 5 per cent of town

roofs were covered with grass and plants, there would be a noticeable reduction

in smog problems. These discoveries have led to heavily-polluted towns in

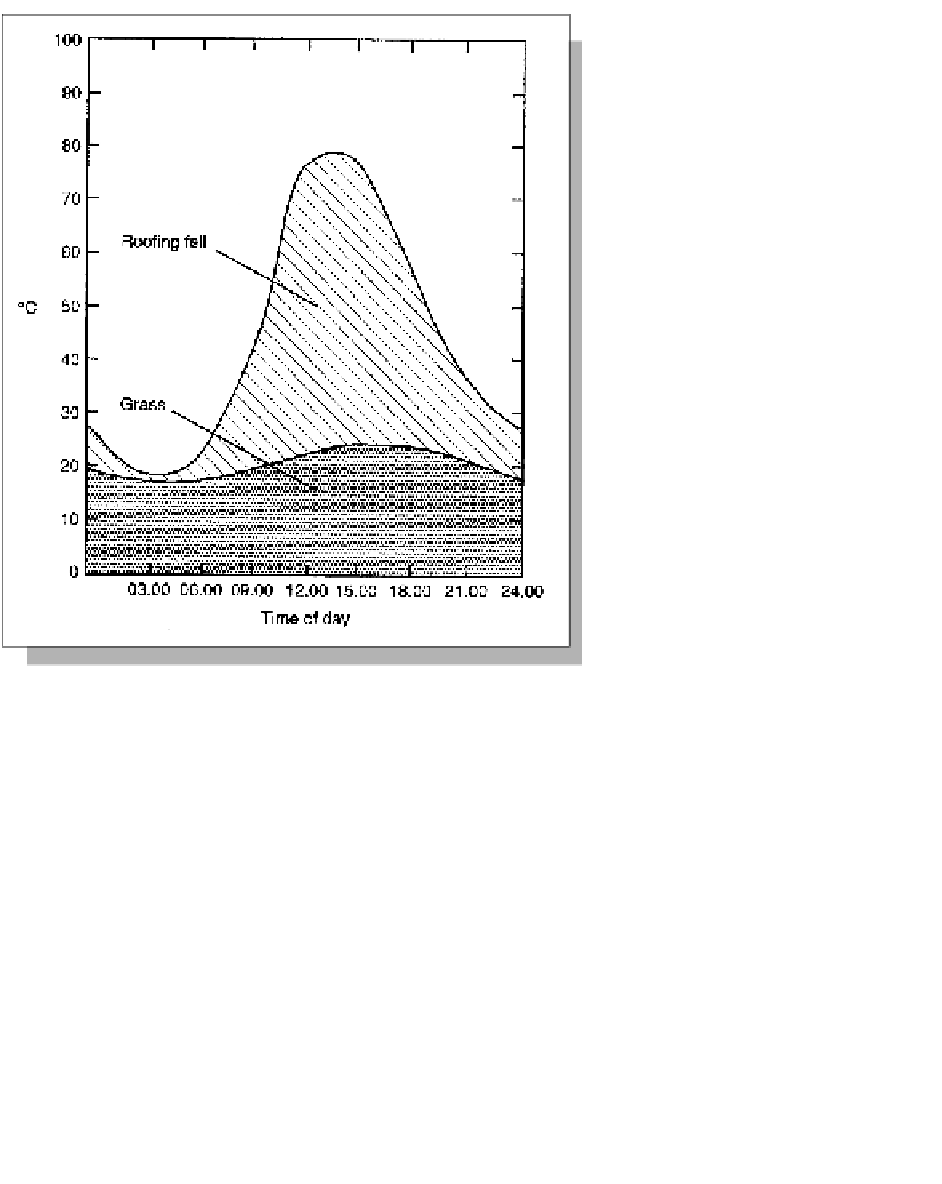

Figure 15.9: Comparison of the temperatures on roofs covered with

bituminous roofing felt and grass during a period of 24 hours, on a

clear summer day.

Source: H. Luz