Civil Engineering Reference

In-Depth Information

After jointing, a dry jointing material is

spread over the whole surface in a

thin layer. This lies in place until the

laying pattern of the tiles becomes vis-

ible. The surface is then cleaned, and

the floor is ready after four days cur-

ing.

Wall tiles are mounted in almost the

same way with the same mix of

cement and sand. It is an advantage if

the back of the tile is textured and has

a semi-porous surface. Laying floor

tiles is relatively straightforward, but

putting tiles up on a wall needs a well-

trained professional.

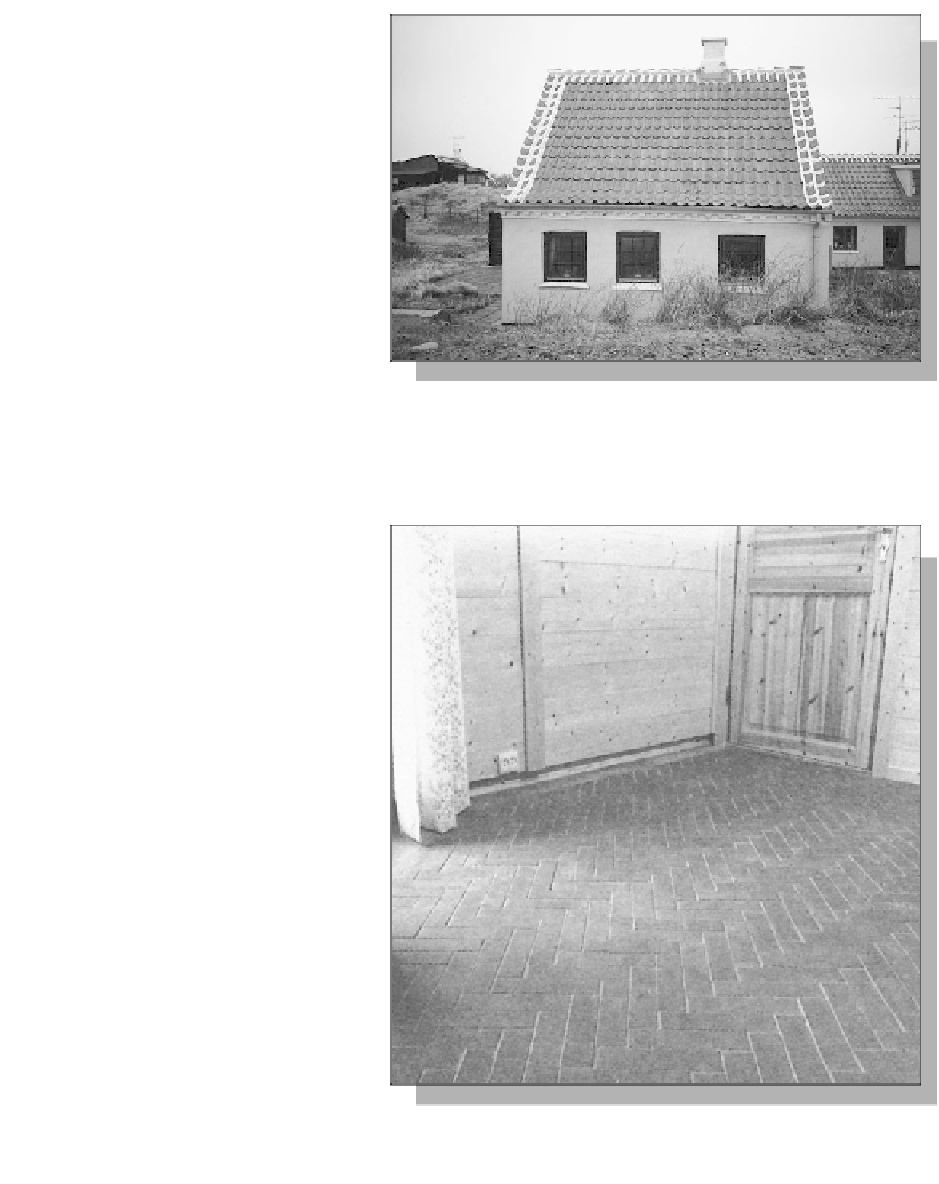

Figure 15.7: In exposed coastal areas of Denmark, the roof tiles

along the ridge and the gables are fixed with lime cement mortar

to prevent them blowing off.

Floor finish of bricks laid

in sand

A brick floor can be laid without

cement using both well- and low-fired

bricks. It is important to choose a brick

with a smooth surface. A 3-5 cm-thick

layer of sand is spread on a layer of

stabilized insulating loose fill, and the

sand is then dampened and com-

pressed. The size of the grains must

not be more than 5 mm and well-grad-

ed. The bricks are laid and knocked

into place by a rubber hammer and

sand is poured into the joints. The

whole floor is then sprinkled with lin-

seed oil, and this treatment is repeat-

ed twice at intervals of one week. This

binds the sand in the joints and makes

the brick surface easy to clean. It is

also possible to treat just the joints

with linseed oil, and treat the bricks

with a soft soap. This floor surface can

be used in both houses and public

buildings.

Earth surface materials

An earth rich in clay can be

rammed into a reasonably good

Figure 15.8: Floor covering of bricks in sand, which are easy to

remove and re-use.

Source: Gaia Lista, 1988