Civil Engineering Reference

In-Depth Information

Table 14.4:

The use in building of fired clay climatic products

Product

Areas of use

Low/medium fired brick

Balancing of humidity

Brick with high lime content (15-20% lime)

Balancing of humidity

Bricks containing materials such as sawdust, peat, hacked

straw and powdered coal, that are burnt out during

Thermal insulation

the firing process

Bricks with fossil meal as an insulating aggregate

Thermal insulation

Expanded clay, loose

Thermal insulation, capillary break

Lightweight concrete

Thermal insulation

Zytan block

Thermal insulation

Insulating aggregate such as fossil meal can be added, and once fired the blocks

have a relatively high thermal insulation value.

Fired clay blocks with fossil meal as thermal insulation

One part clay is mixed with 15 parts fossil meal into a homogeneous mass. It is also possi-

ble to add 25 per cent sawdust or pieces of cork before the mass is pressed into forms and

fired. Hard blocks can be used structurally,

while the blocks with sawdust or cork pieces

are primarily used for insulation. In addition to

these solid blocks, the material can be formed

into blocks with holes.

Fossil meal which naturally contains the

right amount of clay to enable formation

directly into blocks is known as sandy clay.

In Scandinavia this form of fossil meal

occurs only at one site, Jylland in

Denmark, and the sources are not very

plentiful.

Light expanded clay

Expanded clay can be used as loose fill

or cast with cement into blocks or

other structural units. It has a relative-

ly high thermal insulation value. Loose

expanded clay pellets can be used

under the slab of a building as a capil-

lary break. Light expanded clay and

light clay thermal blocks have good

structural properties, but they are poor

moisture regulators because the pore

structure is closed.

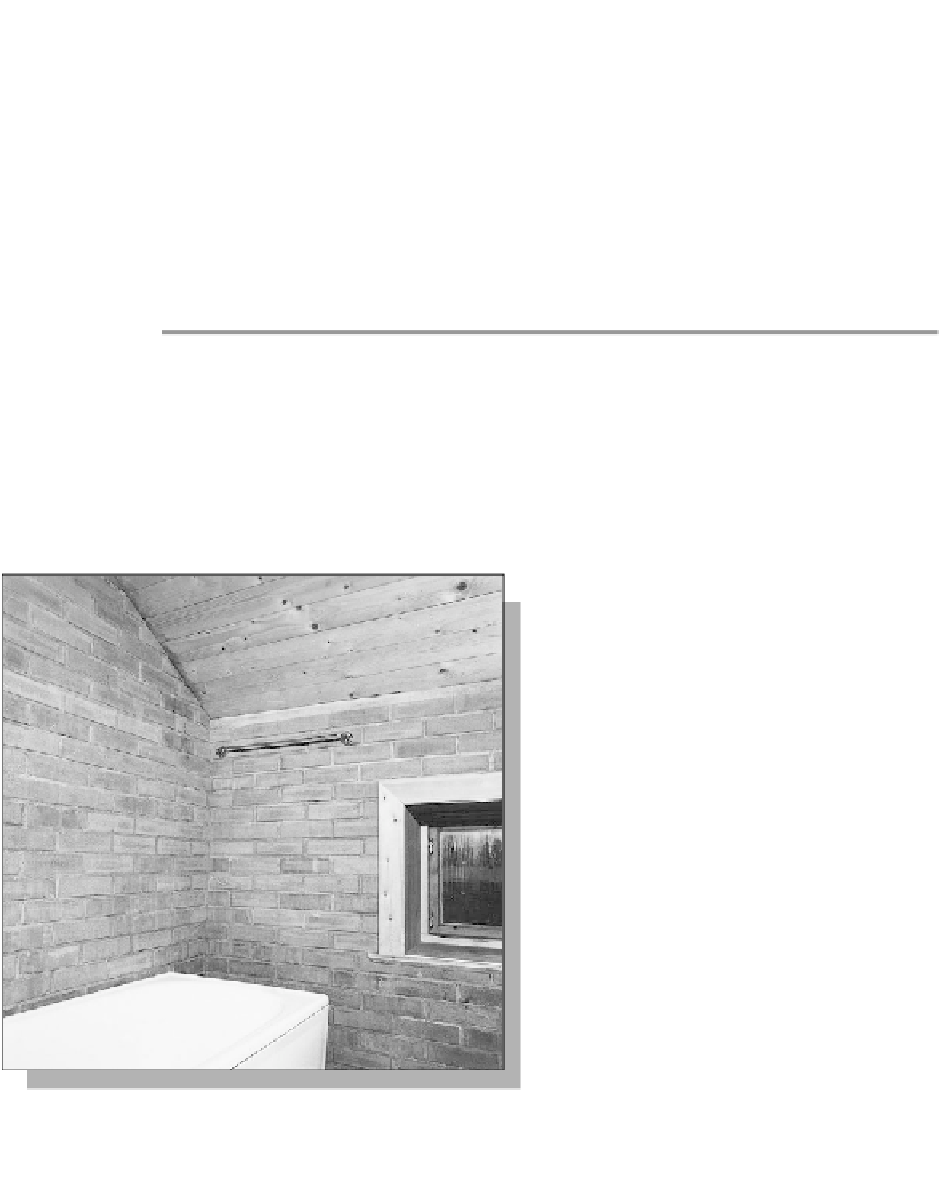

Figure 14.8: Highly porous bricks balance humidity in a

bathroom. Hydraulic lime mortar is used to improve the

possibilities for re-use. Source: Gaia Lista, 1990