Civil Engineering Reference

In-Depth Information

Stovewood house and firewood shed

Stovewood houses came from the last

century. They represent a recycling

building tradition and were built of bits

of plank and spill from the sawmills,

using a mortar of pure clay mixed with

water and sawdust or chaff. The wall

was more stable laterally than log con-

struction, but needed a couple of years

to settle before wallpapering and pan-

elling.

Stave construction

This is a braced skeletal construction

filled with vertical boards or plank

tongued into a bottom and top plate. In

modern post and lintel construction the

space between is usually filled with

boards and insulation which also

braces the structure. The timber com-

ponents are heavy and well-suited to

recycling, providing that appropriate

methods of fixing are used.

Structural framework

This consists of studs mounted

between a top plate and a bottom

plate and bracing. There have been

many variations on this theme

through time. The tendency has been

toward small dimensions of timber

components and more rational

design. This has reduced the quality

of the structure to a certain extent,

particularly in relation to its strength. The distance between the studs can vary some-

what, from 300 mm to 1.2 m. Studwork was previously braced with diagonal lengths of

timber, but nowadays it is more usually braced with sheets of fibre-, plaster- or chip-

board.

The spaces in the wall are filled with different types of insulation. In earlier times they

were filled with clay (in wattle walls), firewood, or bricks (known as half-timbered brick

construction).

Structural framework uses timber very economically, but is seldom easy to recycle. The

many and very strong fixings used make the material good only for energy recycling, i.e.

burning. The timber used in frame construction has to have high-quality strength. It should

not be too elastic or deform too much when exposed to moisture. The timbers best suited

for this are fir, spruce, larch and oak. For smaller structures, birch, aspen, ash and lime

can be used.

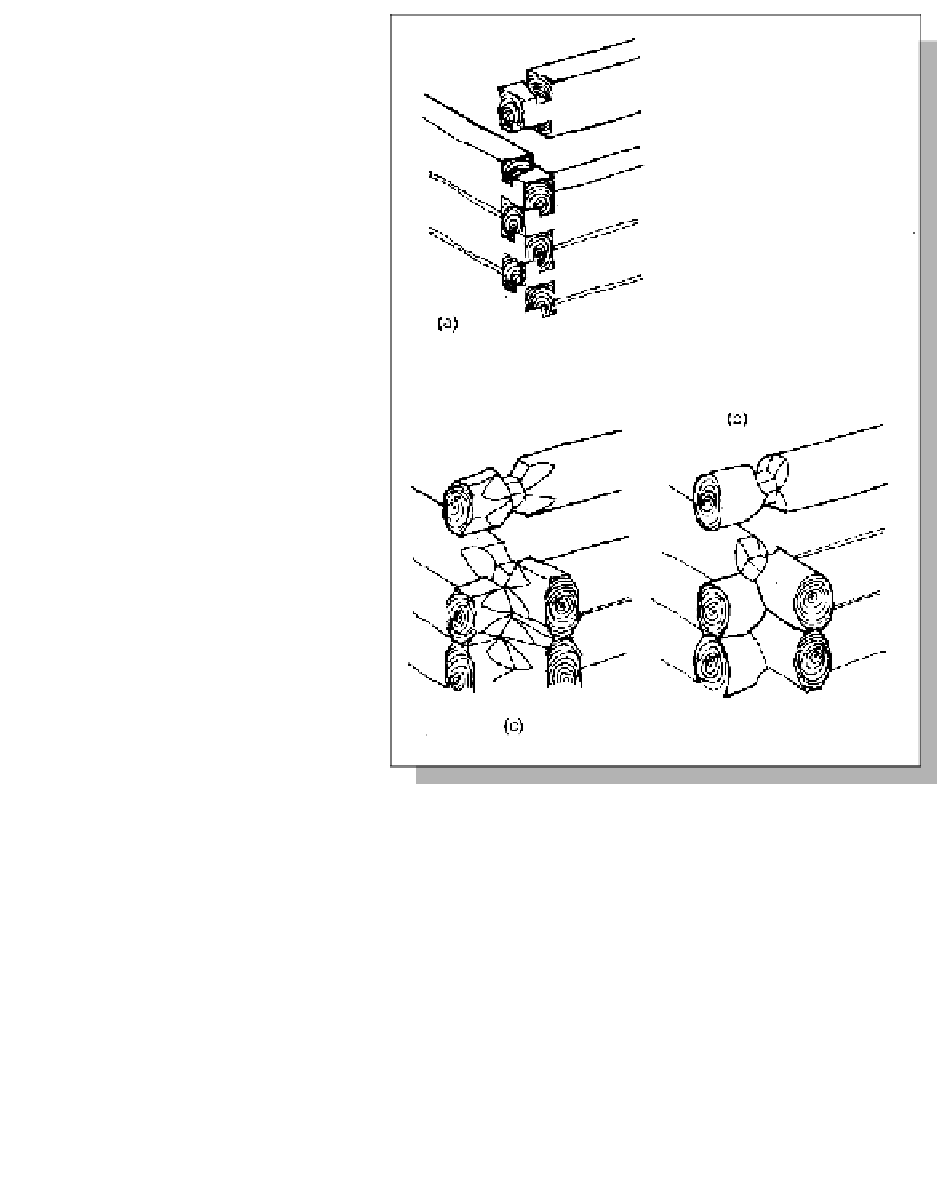

Figure 13.38: Some log joints.