Civil Engineering Reference

In-Depth Information

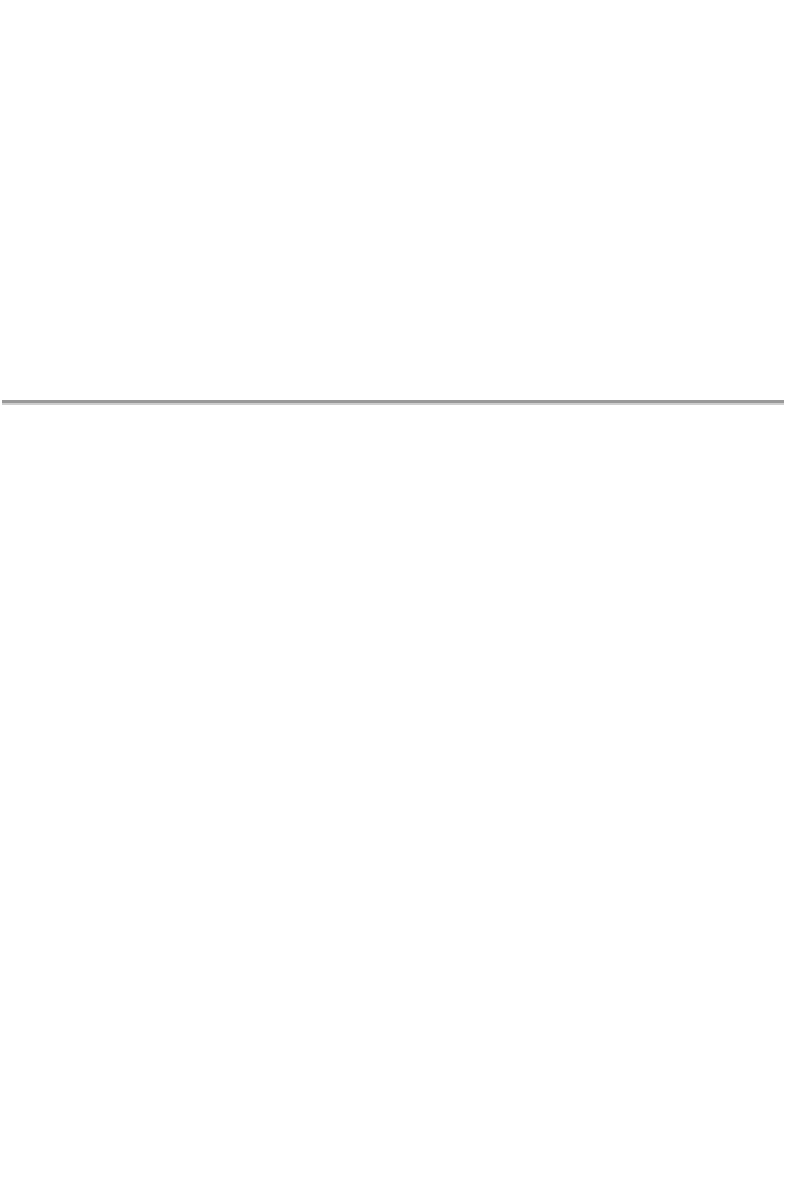

Table 12.1:

Industrial by-products and their uses in building

Material

Industry

Areas of use

Gypsum

Zinc works, oil- and coal-fired power

station, brick factory, production of

artificial fertilizer

Oil- and gas-fired power station,

refineries

Production of ferro-silica and silica

Plasterboard, Portland cement

Sulphur

Sulphur-based render, sulphur-based

concrete, paper production

Reinforcement in concrete products,

pozzolana

Pozzolana, thermal insulation (slag

wool)

Pozzolana

Pozzolana, thermal insulating

aggregate in render and concrete

Silicate dust

Blast furnace slag

Iron foundries

Fly ash

Fossil meal

Coal-, oil- and gas- fired power stations

Oil refineries

Power station gypsum has similar technical properties to natural gypsum.

Even the content of heavy metals and radioactivity is about the same as in the

natural substance. Power station gypsum is therefore appropriate for both plas-

terboard and plaster and as a raw material for Portland cement.

Phosphorous gypsum has a higher likelihood of unwanted constituents

because of the raw material used. Gypsum is also a by-product of other indus-

tries, e.g. in the production of phosphoric acid and titanium oxide, but contains

large quantities of unwanted materials such as heavy metals.

Sulphur

Sulphur has been used for a long time in the building industry to set iron in con-

crete, e.g. for setting banisters in a staircase. At the end of the nineteenth centu-

ry the first sulphur concrete blocks came onto the market.

Sulphur has a melting point of a little less than 120°C, and when melted binds

well with many different materials. It can replace other materials used in casting,

e.g. Portland cement. Sulphur concrete is waterproof and resistant to salts and

acids. It should not be used with alkaline substances such as cement and lime.

Sulphur can also be used in mortar and render, but because of its short setting

time this can cause practical problems.

Sulphur dioxide is emitted in large quantities from industries where gas and

oil are burned, but it is possible to clean up 80-90 per cent of these emissions.

The temperature for working molten sulphur is around 135-150°C. There is

probably little chance of the emission of hazardous doses of either hydrogen

sulphide or sulphur dioxide at these temperatures, though even the slightest

emission of the former gives a strong, unpleasant smell. The workplace should