Civil Engineering Reference

In-Depth Information

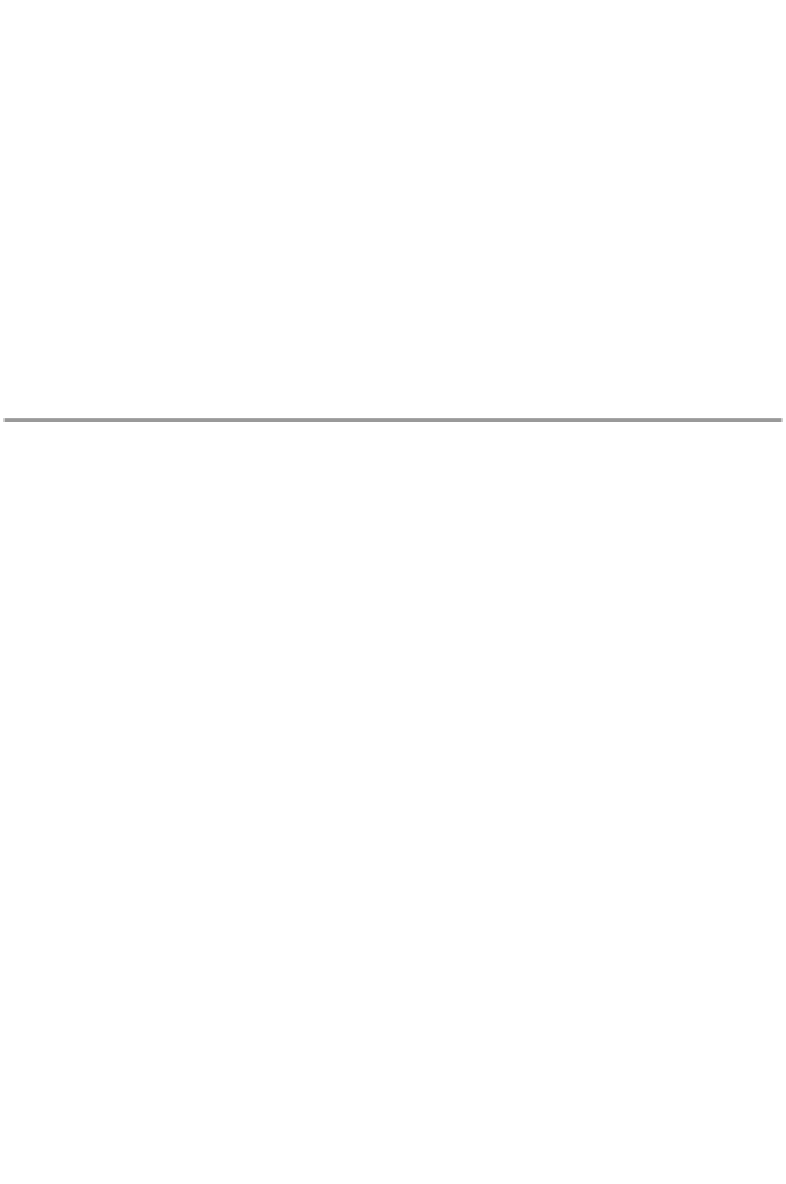

Table 9.9:

Other registered pollution from plastics

Type of plastic

Pollution

Polyester (UP)

Styrene (P)(H), dichloromethane (P)

Epoxy (EP)

Phenol (P), epichlorohydrin (P), amines (H)

Polyamide (PA)

Benzene (H), ammonia (H)

Polymethylmethacrylate (PMMA)

Acetonitrile (P), acrylonitrile (P)

Ureaformaldehyde (UF)

Formaldehyde (P)(H)

Melamineformaldehyde (MF)

Phenol (P), formaldehyde (P)

Polysulphide (T)

Toluene (P)(H), chloroparaffin (P)(H)

Silicone (Si)

Xylene (P)(H)

Styrene rubber (SBR)

Styrene (P)(H), xylene (P)(H), butadiene (P), hexane (P)(H),

toluene (P)(H)

Isoprene rubber

Xylene (P)(H), nitrosamines (P)

Ethylene propylene rubber (EPDM)

Benzene (P), hexane (P), nitrosamines (P)

Chloroprene rubber (CR)

Chloroprene (P)(H), nitrosamines (P)

Polycarbonate (PC)

Possible bisphenol-A (H)

(P), in production; (H), in the house

Polyurethane (PUR)

Polyurethane is produced in a reaction between different polyethers (4 per cent)

and isocyanates (40 per cent), using organic tin compounds as the catalyst.

Antioxidants and flame retardants are also used. Phenol propionate is the usual

antioxidant, and the flame retardant is an organic bromine compound.

Chlorofluorocarbons, pentane gas or carbon dioxide, in a proportion of 10-15 per

cent, are used to foam up the plastic.

Materials released during production are chlorinated hydrocarbons, phenol,

formaldehyde and ammonia, possibly even organic tin compounds and chloro-

fluorocarbons. Workers are exposed, amongst other things, to isocyanates.

Small emissions of unreacted isocyanates and amines can seep from the fin-

ished product and within the building, along with a smaller seepage of chloro-

fluorocarbons, if they were used for foaming-up. Environmentally-damaging

substances can be washed out of the waste product. Polyurethane has a long

decomposition period.

Polyvinyl chloride (PVC)

PVC is produced by a polymerization of vinyl chloride, which in turn is pro-

duced from 51 per cent chlorine and 43 per cent ethylene via ethylene chloride.

Many additives are also used, in some cases up to 50 per cent plasticizers, 0.02

per cent antioxidants and ultraviolet stabilizers, a maximum of 10 per cent flame

retardants, 2.5-10 per cent smoke reducers, a maximum of 4 per cent anti-static

agents, pigment 0.5-1 per cent and a maximum of 50 per cent fillers. Constituents

that are critical for the environment are substances such as plasticizers contain-

ing phtalaths, ultraviolet stabilizers containing cadmium, lead or tin (in the case