Civil Engineering Reference

In-Depth Information

large. In modern brick factories, spe-

cial drying houses are kept very hot

for two to five days.

Firing

When clay is heated up to boiling

point, the water in the pores evapo-

rates, and at 200-300°C the hydrate

water evaporates. After this change

the clay will not revert to a soft clay

with the addition of water, unlike an

air dried earth block. Even in the

Roman Empire bricks were not fired

in temperatures higher than

350-450°C, and this is the case in a

great many buildings that still stand

today, e.g. the Roman Forum.

If fired at higher temperatures, the particles in the stones are pushed nearer to

each other and the brick becomes harder. Between 920 and 1070°C the material

begins to sinter. If the temperature is increased even further, the blocks will

smelt. Higher temperatures are used in the production of fire-proof bricks and

porcelain, using special clay mixtures. To a well trained ear, the temperature at

which a brick was fired can be assessed by hitting it with a hammer. The higher

and purer the sound, the higher the temperature of the firing. This is especially

useful when recycling old bricks.

Clay containing iron turns red when fired, whereas clay containing more than

18 per cent lime turns yellow. There are many different colour variations, deter-

mined by the amount of oxygen used during the firing process. Red brick can

vary from light red to dark brown.

Chamotte is produced from clay with a low iron and lime content. This can

withstand temperatures of up to 1900°C and is classified as fire-proof.

In certain products the brick can be glazed or coloured by the manufactur-

er using compounds such as oxides of lead, copper, manganese, cadmium,

antimony and chromium. To set the glaze onto the brick requires a secondary

firing until the glaze smelts. The temperature of this firing should be well

under the brick's firing temperature so that it does not lose its form or slide

out.

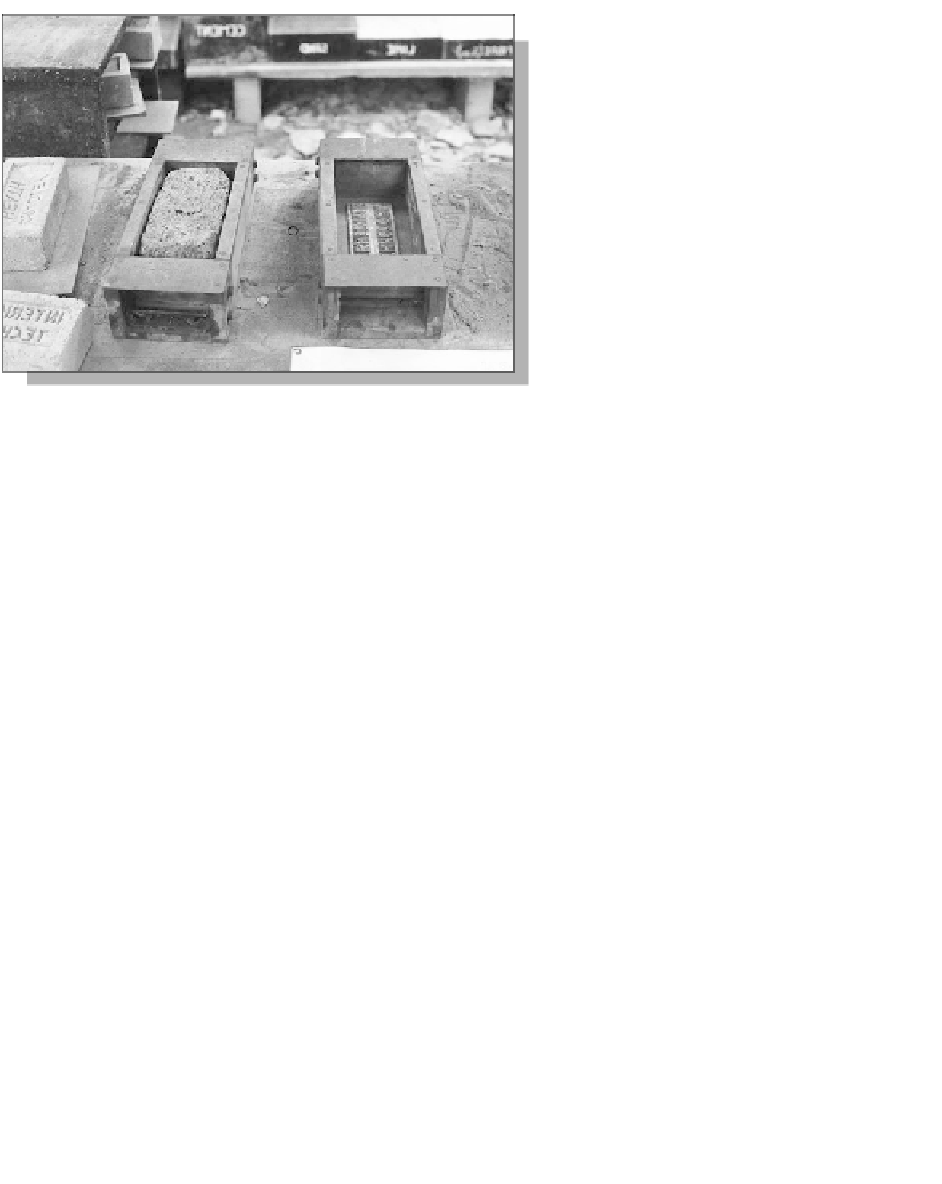

Figure 8.8: Wooden mould for handmade bricks.

Kilns

Many different types of kiln have been used over the years, but almost all belong

to one of three main types: the open charcoal kiln, the circular kiln or the tunnel