Civil Engineering Reference

In-Depth Information

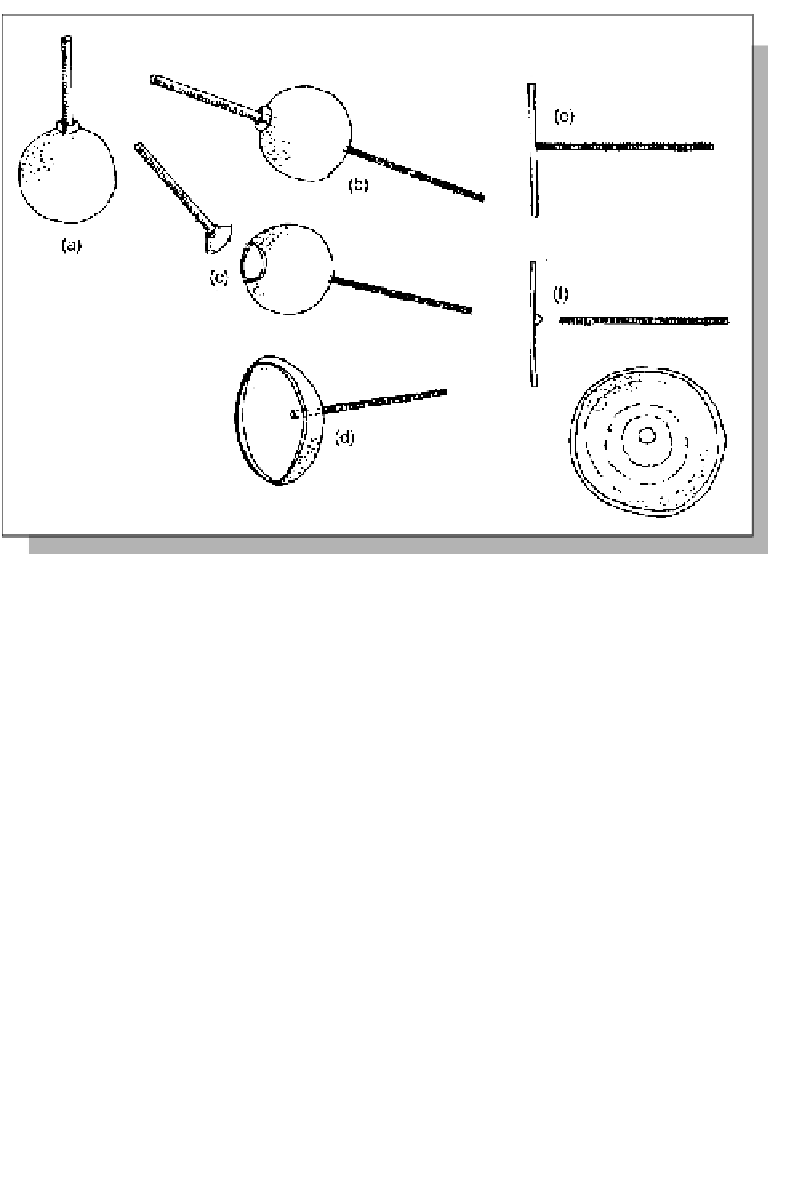

Figure 6.5: The production of crown glass: (a) the glass is blown up into a bubble; (b) an iron

rod is fixed to the glass bubble; (c) the blowpipe is removed; (d) the glass bubble opens up after

being warmed and rotated; (e) when completely open, the bubble becomes a flat, circular pane

of glass; (f) the iron rod is removed. The pane of glass has a thick edge and centre, but is

otherwise clear.

Smelting

As early as the Middle Ages, glass-works used 'pot kilns'. The method is compa-

rable to ordinary cooling. The pot is warmed up by a fire or gas flame. Dry glass

mix is poured into the pot and heated to 1400-1500°C. Recycled glass only needs

1200°C. When the mass has become even and clear, the temperature is lowered,

and the substance removed in small portions and cast into a mould. In theory, the

glass is soft and can be worked until the temperature reaches 650°C. The usual

working temperature in the production of windows is about 1000°-1200°C. The

capacity of a pot kiln is about half a ton per day. They are still used in smaller

glass-blowing workshops for glass goods, but not in the production of windows.

In more industrial smelting methods, closed tanks with an inbuilt oil burner or

electrical element are used. The tank is made of fireproof stone and has a capac-

ity of 200-300 tons per day. The working temperature etc. is the same as that of

the pot kiln. A tank kiln will be worked at full capacity continuously and may

only last two to three years. The glass produced can be shaped using a series of

different techniques.