Biomedical Engineering Reference

In-Depth Information

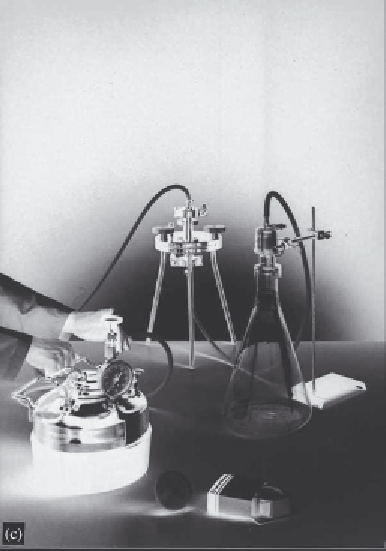

Figure 6.24

(

Continued

)

6.9.4 Freeze-drying

Freeze drying (lyophilization) refers to the removal of solvent directly from a solution while in

the frozen state. Removal of water directly from (frozen) biopharmaceutical products via lyophi-

lization yields a powdered product, usually displaying a water content of the order of 3 per cent.

In general, removal of the solvent water from such products greatly reduces the likelihood of

chemical/biological-mediated inactivation of the biopharmaceutical. Freeze-dried biopharmaceu-

tical products usually exhibit longer shelf lives than products sold in solution. Freeze-drying is

also recognized by the regulatory authorities as being a safe and accep

table

method of preserving

many parenteral products.

Freeze-drying is a relatively gentle way of removing water from proteins in solution. However,

this process can promote the inactivation of some protein types, and specifi c excipients (cryopro-

tectants) are usually added to the product in order to minimize such inactivation. Commonly used

cryoprotectants include carbohydrates (such as glucose and sucrose), proteins (such as HSA), and

amino acids (such as lysine, arginine or glutamic acid). Alcohols/polyols have also found some

application as cryoprotectants.

The freeze-drying process is initiated by the freezing of the biopharmaceutical product in its

fi nal product containers. As the temperature is decreased, ice crystals begin to form and grow. This

results in an effective concentration of all the solutes present in the remaining liquid phase, includ-

ing the protein and all added excipients. For example, the concentration of salts may increase to

Search WWH ::

Custom Search