Biomedical Engineering Reference

In-Depth Information

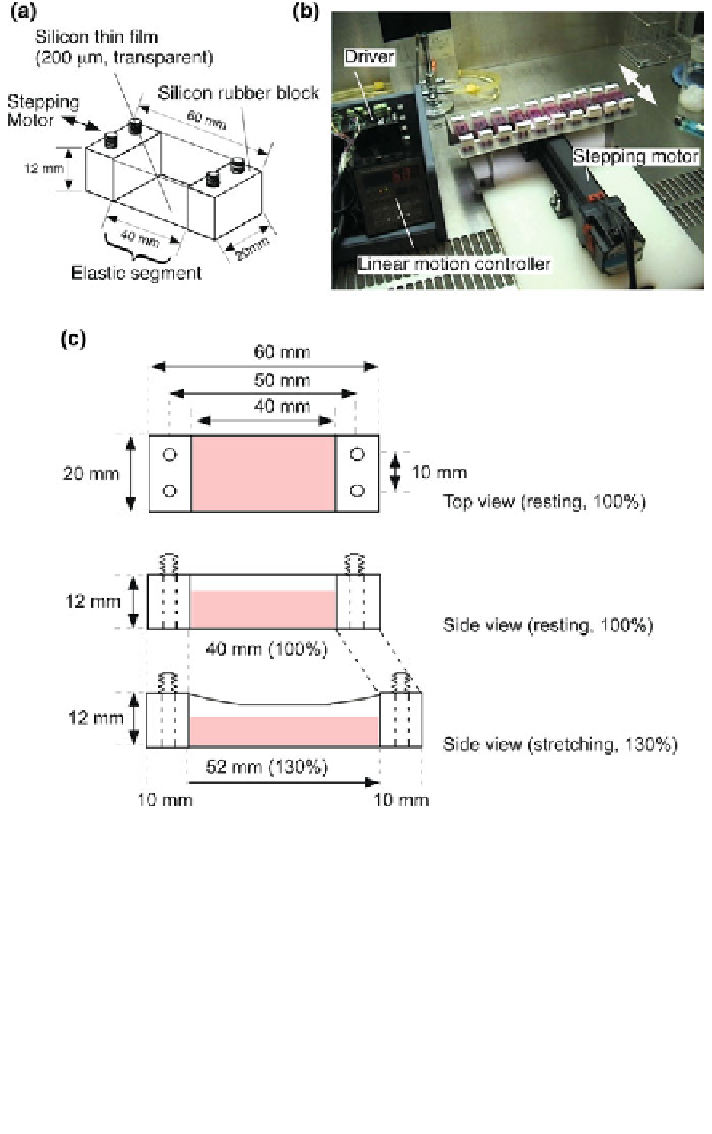

Fig. 1 Schematic drawing of stretch chamber and photographic images of the stretch apparatus for

cultured cells. Adaptation of uniaxial cyclic stretch of 3T3-L1 cells was carried out according to the

method of Naruse et al. [

22

], with a modification of the collagen coating procedure [

21

]. Briefly,

both type I collagen (0.3 %, Nippon Ham, Tsukuba, Japan) and type IV collagen (0.3 %, Nitta

Gelatin Inc., Osaka, Japan) were mixed at a 10:1 ratio in an acidic condition (pH 3.0), then diluted

with ice chilled phosphate-buffered saline and dispensed in a 2.5 mL aliquot to each sterilized

chamber (from 1 to 10) having an elastic square bottom (20 mm 9 40 mm), which was made from

a thin film (200 lm-thick) of silicon rubber with good transparency (a). The chamber was incubated

at 37 C in the humidified CO

2

-incubator (5 % CO

2

/95 % air) to facilitate a formation of collagen

fibril. After microscopic checking of each chamber, the collagen cocktails were air dried on a clean

bench, washed 3 times with distilled water, and then used for the cell seeding. All coating

procedures were carried out under a sterilized condition. The 3T3-L1 cells (6-8 9 10

5

) were

seeded onto the coated elastic chamber and allowed to reach confluence (c). The cells in various

conditions were treated with or without uni-axial cyclic stretching by use of an in-house stretch

device connected to a linear stepping motor and a programmable linear motion controller (b)

Search WWH ::

Custom Search