Chemistry Reference

In-Depth Information

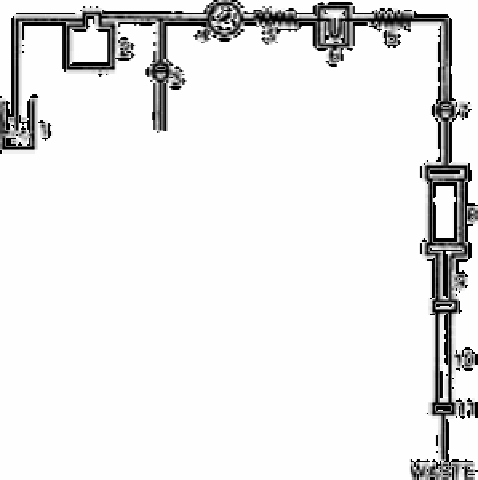

Fig. 12.9

Scheme of the column packing apparatus. 1, reservoir (methanol or

water); 2, pump; 3, valve; 4, manometer; 5, capillary; 6, pulse

dampener; 7, valve, 8; slurry reservoir; 9, precolumn; 10, column; 11,

plug of wool in low dead volume connector

Source: Reproduced with permission from Elsevier Science [11]

homogenised by sonication. The column and precolumn are filled with

tetrachloromethane in order to prevent inclusion of air bubbles in the packed bed. The

slurry reservoir is filled with the slurry and thereafter methanol is added to remove all air

up to the shut off valve. When the pump and dampers have been filled with methanol, the

slurry reservoir is connected to the pump (with valve 7 closed). The apparatus is

pressurised with methanol up to 400bar. Thereafter, valve 7 is opened and the slurry is

forced into the column. The packed bed is settled by flushing 200ml of methanol and

200ml of water through the column at maximum pressure.

Glass columns can also be slurry packed by this method when the pressure across the

column is kept below 60bar. A short glass column (100 ×4.0mm) packed with Zipax

SAX was used as a concentrator column.

T

he void volume of the separator column (V

m

) is estimated from the retention volume

of water. The capacity ratio k is calculated from the equation

k

=(V

R

−V

M

)/V

m

, where V

R

and V

M

are the retention volumes of the solute and water respectively in the separator-

suppressor column combination. The

k

values are independent of sample size (50-200µL

of solutions of 10mg L

−1

nitrate and 10mg L

−1

sulphate), only slightly dependent on the

eluent flow rate (1.5-4.5ml min

−1

), and reproducible within 3%.

Search WWH ::

Custom Search