Chemistry Reference

In-Depth Information

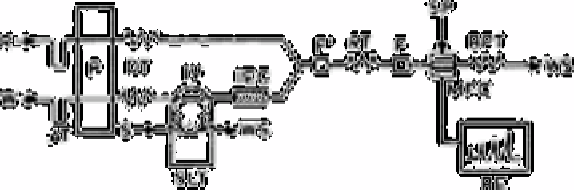

Fig. 2.52

Schematic flow diagram. R, reagent solution; W, water saturated with

BaSO

4

; AT, air trap; P, double plunger micro pump; DT, damping

coil; IV, injection valve; S, sample injection; SLT, sample injector

(1.0mm tubing 130µL); WS, waste; IEC, cation exchange resin

column; F, line filter; RT, reaction coil; SP, spectrophotometer;

MFC, micro flow cell; BPT, back pressure soil; RE, recorder

Source: Reproduced with permission from Springer Verlag [773]

sodium, 80mg L

−1

of potassium and 100mg L

−1

(maximum concentrations tested) of

chloride, nitrate, phosphate, hydrogen carbonate and silicate. These ions therefore did not

interfere with sulphate determination at levels which are normally present in non saline

waters. The lifetime of the cation exchange resin column was found to be at least two

months when regularly used.

Calibration graphs were linear over the sulphate range 0-14mg L

−1

and slightly curved

over the range 14-32mg L

−1

. The relative standard deviations of 20 analyses of solutions

containing 6 and 10mg L

−1

of sulphate were 0.94 and 1.2% respectively. The detection

limit was found to be about 0.2mg L

−1

of sulphate ion. The sampling rate was 20-30

samples per h.

Sonne and Dasgupta [774] carried out a simultaneous photometric flow injection

determination of sulphate, sulphide, polysulphide, sulphite and thiosulphate.

Eremina

et al.

[775] used flow injection spectrophotometry to determine sulphate at

concentrations of 0.5-20mg L

−1

; the sulphate in non saline waters masked the reaction of

barium with Orthanilic K.

Van Staden [776] presented a procedure for the on-line automated monitoring of

sulphate in effluent streams by reversed flow injection. The sampling capacity was 60

sulphate determinations per h, with alternate sampling of the barium chloride reagent and

the buffer EDTA solution. Results compared favourably with those of normal flow

injection and a standard automated segmented method.

Tang and Huang [777] have described a method for determining sulphate based on a

potentiometry-based linear calibration graph. These workers point out that although

various potentiometric procedures have been developed, a non-linear or semi-linear plot

is usually obtained and used as the calibration graph, or the equilibrium constant for the

reaction of sulphate with lead has to be known or determined in order to linearise the

calibration graph [766-768]. This introduces either unpredictable uncertainties or tedious

procedures. In order to overcome these drawbacks, the derived equations based on the

behaviour of the lead ion electrode and the interaction between a sulphate-containing

Search WWH ::

Custom Search