Biomedical Engineering Reference

In-Depth Information

a

b

100

0.5

t

1

= 10 hours

t

1

= 100 hours

t

1

= 1000 hours

0.4

0.3

50

0.2

0.1

0

0

0

1

2

3

4

0

1

2

3

4

time (weeks)

time (weeks)

c

d

0.02

0.2

0.015

0.15

0.01

0.1

0.005

0.05

0

0

0

1

2

3

4

0

1

2

3

4

time (weeks)

time (weeks)

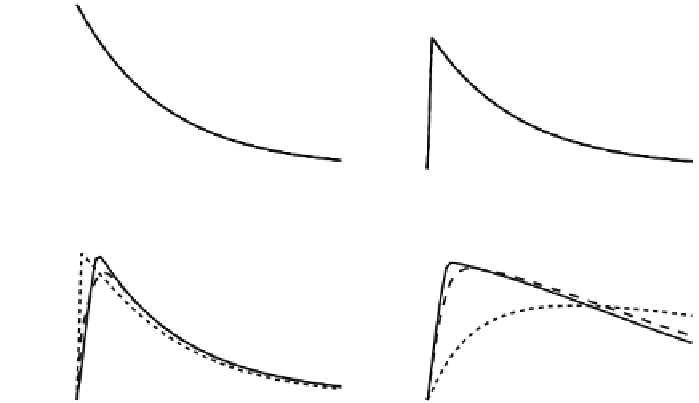

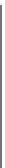

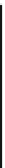

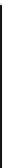

Fig. 5

Sensitivity analysis of the phase-changemodel in both layerswith respect to the characteristic

drug unbinding time scale

t

1

. Temporal evolution of

a

the solid-phase drug concentration

c

e

;

b

the

liquid-phase drug concentration

c

0

;

c

the free drug concentration

c

1

;

d

the bound drug concentration

c

b

, each time averaged over the entirety of their respective layers. In panels

a

and

b

all three curves

coincide since the time scale change in the medial layer does not feed back into the polymer layer

faster drug binding/unbinding kinetics. At the same time, the free drug concentration

in the wall is barely affected by changes in the drug binding/unbinding kinetics.

On the other hand, if we assume a single liquid-phase

c

0

in the coating, we can

control the drug release kinetics by setting the drug diffusivity

D

0

. Using Higuchi's

formula, we can estimate the characteristic release time of the drug from the polymer

l

0

ˀ

as

t

e

4

D

0

[

18

]. Figure

6

a demonstrates how using a single-phase model and

varying the characteristic release time

t

e

(and with that the diffusivity

D

0

) can in

fact be used to approximate the release profiles obtained with the two-phase model

varying the solid-liquid transfer time. This leads to very similar bound drug dynamics

in the wall (Fig.

6

b). These results indicate that a single-phase model in the coating

can be used to describe the (averaged) release dynamics and leads to a very similar

(averaged) response in the wall. However, from a designer's point of view, the more

detailed information about the solid-fluid transfer time and the porosity might be

more valuable and easier to control.

Moreover, the current simulations show that, although an additional equation

needs to be solved, the proposed two-phase model in the coating is significantly

simpler to handle numerically, at least in the one-dimensional case. The reason for this

lies in the otherwise very steep concentration gradient at the coating-wall interface.

The steep gradient requires a significantly larger number of elements and smaller

=