Civil Engineering Reference

In-Depth Information

72°

Internal

External

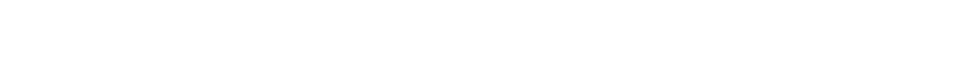

Figure 12-2 Two beneficial effects of thermal mass are to reduce the peak interior temperature shifts

and to delay the time that the peak occurs.

orientation may affect the amount of daylight that illuminates the space versus the amount of artificial

lighting needed—and the way in which natural light contacts surfaces plays into thermal mass considerations.

MATERIALS AND RESOURCES

The key ingredient in concrete is cement. It is the glue that binds water and aggregates into a solid mass. While

cement manufacturing is energy intensive, improvements in the process over many decades have resulted in

green house gas (GHG) reductions per ton of material produced (Ref.12.5). And the bulk of concrete is

comprised of aggregates, which are very low embodied energy materials. Supplementary cementing materials

(SCMs), which are typically by-products of other industries, can replace a portion of cement to lessen

concrete's environmental footprint.

In the U.S., fresh concrete is locally available most everywhere, with the average distance from a ready mix

plant to a project site being 14.4 miles (Ref.12.6). Most concrete ingredients are abundant, locally sourced, and

require minimal processing and transportation. Most materials used in the production of reinforced concrete

are also recycled or recyclable. As just noted, SCMs often come from other industries and using them in

concrete reduces landfill burdens. Crushed concrete can replace a portion of virgin aggregate in new concrete,

but it is more commonly used as base material for new pavement. Steel reinforcement (rebar)

is made predominantly from recycled rail steel. Recycling water from production and clean-out operations is

becoming more common in the ready mix industry, although it must meet certain chemical requirements

for use in concrete. Ultimately, reinforced concrete has a large potential for recycled content—and it can be

recycled at the end of a structure's life, too.

Concrete systems for medium to taller buildings are especially desirable because the repetition allows for

formwork reuse. Climbing form technology offers speed and economy, which saves money for the building

and is resource efficient. It also implies that designers strive for repetition in building layout from one floor

to the next, which also leads to simplicity of design. And whether concrete is cast at the site or offsite,

panelizing the design can lessen material waste.

Search WWH ::

Custom Search