Civil Engineering Reference

In-Depth Information

tile, etc. should be accomplished by adding concrete to the top surface of the slab rather than maintaining a

constant slab thickness and forming offsets in the bottom of the slab. Cross section (a) in Fig. 9-2 is less costly

to form than cross section (b).

h

(a)

h

h

(b)

Figure 9-2 Depressions in Slabs

When drop panels are used in two-way systems, the total depth of the drop h

1

should be set equal to the actual

nominal lumber dimension plus

3

/

4

-in. for plyform (see Fig. 9-3). Table 9-2 lists values for the depth h

1

based

on common nominal lumber sizes. As noted above, designs which depart from standard lumber dimensions are

expensive.

Slab

h

1

Plyform

Drop

16'-6” or greater

*Keep drop dimensions constant

Figure 9-3 Formwork for Drop Panels

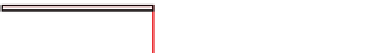

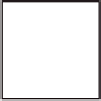

Table 9-2 Drop Panel Depth, h

1

Nominal lumber

size

Actual lumber

size (in.)

Plyform

thickness (in.)

h

1

(in.)

2X

1½

¾

2¼

4X

3½

¾

4¼

6X

5½

¾

6¼

8X

7¼

¾

8

Search WWH ::

Custom Search