Civil Engineering Reference

In-Depth Information

Refer to Table 4-7:

b

1

= b

2

= 16 + 9.5 = 25.5 in. = 2.13 ft

A

c

= 4(25.5)

9.5 = 969 in.

2

J/c = [25.5

9.5(25.5

4) + 9.5

3

] /3 = 8522 in.

3

V

u

= (84,700/969) + (0.4

178.5

12,000/8522)

= 87.4 + 100.5 = 187.9 psi < 215 psi

Note that the shear stress around the drop panel is much less than the allowable stress (calculations not

shown here).

With drop panels, a lesser slab thickness for deflection control is permitted. From Table 4-1 (flat slab with

spandrel beams): h = ˜

n

/36 = (22.67

12) /36 = 7.56 in. could possibly reduce slab thickness from 8

1

⁄

2

to 8

in.; however, shear strength may not be adequate with the lesser slab thickness. For this example hold the

slab thickness at 8

1

⁄

2

in. Note that the drop panels may not be required in the upper stories where the transfer

moment due to wind become substantially less (see Fig. 2-15).

Use 8

1

⁄

2

in. slab with 2

1

⁄

4

in. drop panels at interior columns of 1st story floor slab. Drop panel dimensions

= ˜ /3 = 24/3 = 8 ft. Use same dimension in both directions for economy of formwork.

Check for fire resistance: From Table 10-1 for fire resistance rating of 2 hours, required slab thickness

= 4.6 in. < 8.5 in. O.K.

3. Factored moments in slab due to gravity load (N-S direction).

(a) Evaluate spandrel beam-to-slab stiffness ratio

α

and

β

t

:

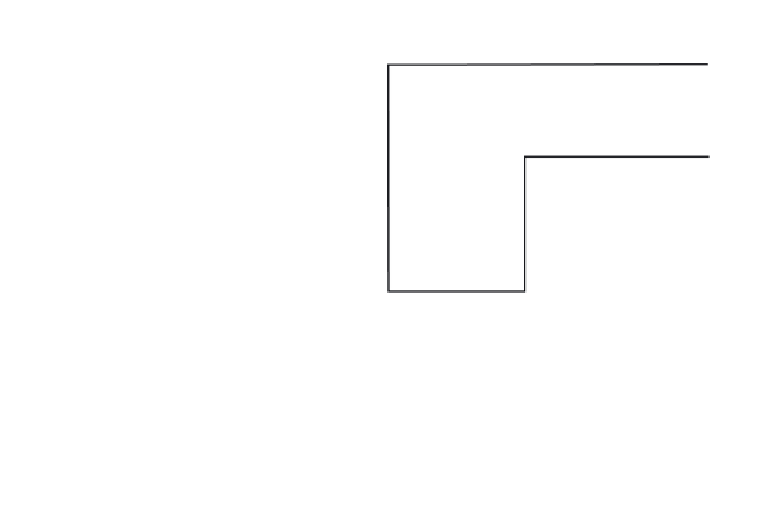

Referring to Fig. 4-7:

23.5"

12 + 11.5 < 12 + 4(8.5)

˜

2

= (20

12) /2 = 120 in.

a = 20 in.

b = 12 in.

h = 8.5 in.

a/h = 20/8.5 = 2.4

b/h = 12/8.5 = 1.4

12"

f

1.37

b

2

12

120

( )

()

( )

= 1.89 > 0.8

3

3

α=

a/h

f =

24

1.37

f

Note that the original assumption that the minimum h = ˜

n

/33 is O.K. since

α

f

> 0.8 (see Table 4-1).

β

t

C

8425

27,680

21

s

=

)

= 0.55 < 2.5

(

Search WWH ::

Custom Search