Environmental Engineering Reference

In-Depth Information

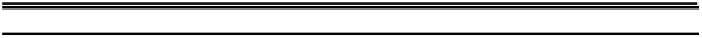

Simple Load Model Results

Load C

ase A - Fatigue Loads on Blades and Rotor Shaft

Fatigue Damage Limit

Fatigue Damage

Conclusion

Blades

1.00

2.25E-06

SAFE

Shaft

1.00

Infinite Life

SAFE

Load C

ase B - Blade and Rotor Shaft Loads during Yaw

Material Stress Limit (MPa)

Calculated Stress (MPa)

Conclusion

Blades

13.33

0.27

SAFE

Shaft

27.78

40.29

FAIL

Load C

ase C - Yaw Error Load on Blades

Material Stress Limit (MPa)

Calculated Stress (MPa)

Conclusion

Blades

13.33

2.77

SAFE

Load C

ase D - Maximum Thrust on Shaft

Material Stress Limit (MPa)

Calculated Stress (MPa)

Conclusion

Shaft

13.33

0.65

SAFE

Load C

ase E - Maximum Rotational Speed

Material Stress Limit (MPa)

Calculated Stress (MPa)

Conclusion

Blades

13.33

4.25

SAFE

Shaft

27.78

1.14

SAFE

Load C

ase F - Short at Load Connection

Material Stress Limit (MPa)

Calculated Stress (MPa)

Conclusion

Blades

13.33

2.49

SAFE

Shaft

27.78

12.78

SAFE

Load C

ase G - Shutdown Braking

Material Stress Limit (MPa)

Calculated Stress (MPa)

Conclusion

Blades

13.33

n/a

n/a

Shaft

27.78

n/a

n/a

Load C

ase H - Parked Wind Loads during Idling

Material Stress Limit (MPa)

Calculated Stress (MPa)

Conclusion

Blades

13.33

3.58

SAFE

Shaft

27.78

1.86

SAFE

Fig. 9.7

The seventh sheet of the SLM spreadsheet

will no doubt become more popular, but it is not easy to implement. Readers

interested in pursuing this topic should start with the programs available from the

excellent NREL site:

http://wind.nrel.gov/designcodes/simulators/

. Some of the

impressive results that can be obtained from aero-elastic simulations are described

Search WWH ::

Custom Search