Hardware Reference

In-Depth Information

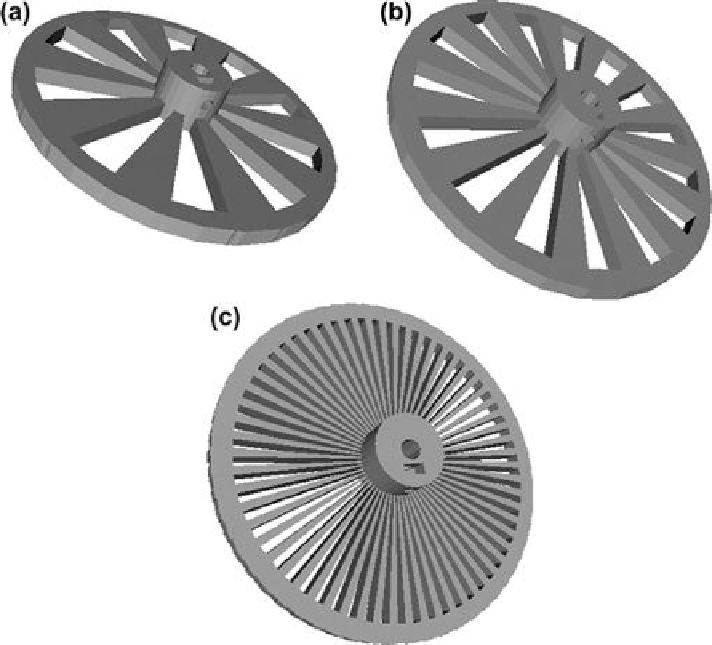

FIGURE 6.3

Rendered parametric design in OpenSCAD on an open-source optical chopper

wheel with (a) 10 slots, (b) 15 slots and (c) 60 slots.

6.1.2 Open-source 3-D printers

which as shown in

Chapter 5

can be constructed for <$600, have made the cost of rapid pro-

ating nature (approximately 50% of its own parts can be self-printed) makes it an extremely

useful platform for open-source fabrication and maintenance of laboratory equipment. The

printing process for the additive layer manufacture of scientific experimental components dis-

cussed in this chapter is a sequential layer deposition. The RepRap extruder intakes a ilament

of the working material, then the Z (vertical) axis will raise, and the extruder will deposit an-

other layer on top of the first. In this way, it can build three-dimensional models from a series

of two-dimensional layers [

3

]

.

Figure 6.4(a)

shows the detail of a RepRap printing out a com-

shows another component of the same filter wheel printing, and also displays the assembly

Search WWH ::

Custom Search