Hardware Reference

In-Depth Information

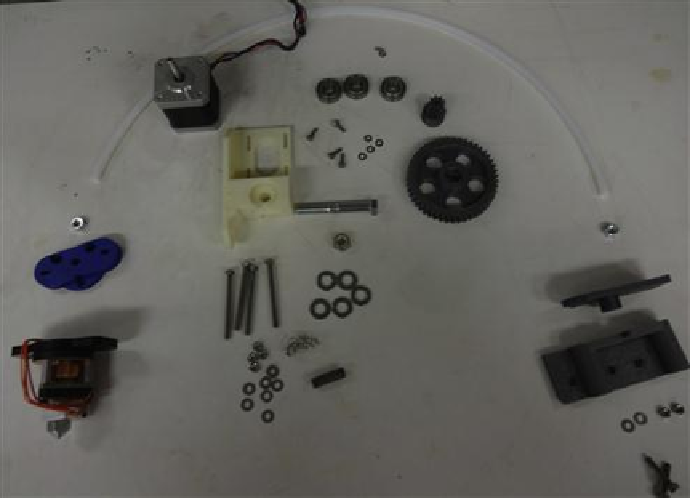

Two M4 × 20 mm screws.

One stepper motor.

Four M3 × 10 mm screws.

Four M3 washers.

One set screw.

M3 nut for small wade gear.

FIGURE 5.32

Bill of materials for the extruder.

Use a pencil sharpener to trim down both sides of the Bowden sheath as shown in

Figure

with a knife. Next, mount a bolt into both ends of the printed sheath holders and plastiform

threads at both ends of the sheath as shown in

Figure 5.34

.

Clean out extruder body holes and

mount M6s in the holes of the extruder mount and hot end mount (

Figure 5.35

)

. Screw the

long M4s screws on the extruder body and the idler carriage (

Figure 5.35

—put all the way on

and then take off—as that piece you want to be freely moving). Now, mount the set screw and

M3 nut in small gear and mount that on the stepper motor shaft and mount the motor to the

extruder body loosely with M3 screws as shown in

Figure 5.36

.

Mount the extruder body on

the extruder mount before ataching it to the frame using two M4 screws washers and nuts.

This will ensure that before you put on the gears, you will be able to mount it on the printer.

Warning

: If you do not do this step, you will need to take the whole extruder apart.

Search WWH ::

Custom Search