Environmental Engineering Reference

In-Depth Information

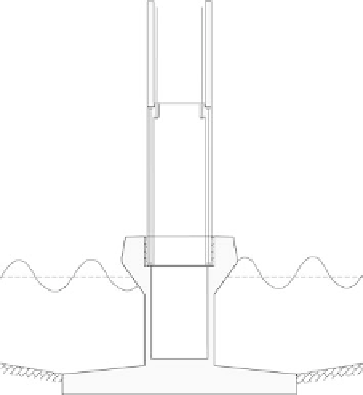

Fig. 5.15 Compact foundation and tower made from prestressed precast concrete elements

5.4.1.2 Sequence of operations on site

1. Installation of foundation with heavy-lift crane vessel

2. Erection of first tower segment, internal prestressing, grouted joint

3. Erection of second tower segment on mortar bed joint, external prestressing

4. Erection of further tower segments with external prestressing

5.4.2 Design, construction, transport and erection

of concrete substructures

High-strength lightweight concretes are frequently used for concrete substructures

because these represent a weight-saving of approx. 20% over normal-weight concretes.

Owing to their very dense microstructure, high-strength lightweight concretes exhibit

excellent durability and are therefore particularly suitable for offshore applications. In

the past, high-strength lightweight concretes have been successfully used worldwide

for oil and gas platforms.

As a rule, the primary loadbearing elements of concrete support structures for wind

turbines are prestressed in order to improve the serviceability (to limit cracks,

deformations, etc.). The actions due to repeated loads (fatigue) are often especially

important when designing the cross-sections (see Section 4.9).

The costs of the materials for and construction of concrete support structures for offshore

wind turbines are comparatively low. Moreover, exploiting series production and pre-

fabrication options can make a considerable contribution to optimising the costs. Contrast-

ingwith this, however, are themuchhigher dead loads of such substructures. They frequently

weighbetweenapprox. 3000and5000 t andare therefore far heavier than steel substructures.

The high self-weight places considerable demands on the fabrication yards and

especially the offshore logistics (transport and erection). There are currently only a