Environmental Engineering Reference

In-Depth Information

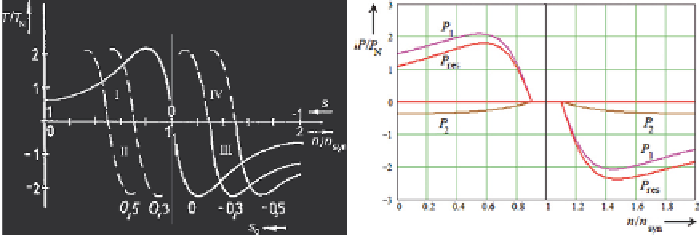

a)

b)

Fig. 5.12

Torque and power characteristics of the cascade system (

a

) Torque characteristics; (

b

)

Power characteristics, example for

k

2

= 0

,

1

5.3.3.3 Doubly-Fed Asynchronous Machine

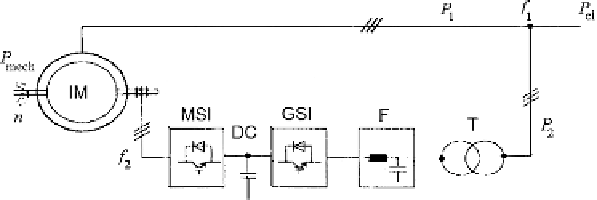

The term doubly-fed induction machine applies to a system where both stator and

rotor winding of a slip-ring machine are supplied. With grid-connected primary

winding and a rotor-side converter adapting the slip power to the grid side the sys-

tem acts as a cascade. Use can be made of a cyclo-converter or a converter with

intermediate d.c. circuit as shown in Fig. 5.13. Both rotor-side and grid-side inverter

(MSI, GSI) are self-controled devices, allowing active power transfer in both direc-

tions and the adjustment of reactive power on both sides. Hence the cascade can,

different from the Kramer system in Fig. 5.9, also operate in supersynchronous mo-

tor and subsynchronous generator mode. Note that Fig. 5.13 contains a filter (F) and

a transformer (T) to adapt the rotor side voltage to the grid. In most cases a crowbar

is additionally provided at the rotor-side, by which in case of grid faults the rotor

is switched to an external resistor to protect the machine-side inverter from excess

current.

For wind energy system purposes the cascade is usually equipped with a VSI

type inverter. A common design realizes a speed interval of ratio 1:2, by means

of a control such that the range between lower and upper speed is approximately

2

/

3

<

n

/

n

syn

<

4

/

3, where

n

syn

is the machine synchronous speed at grid frequency.

Fig. 5.13

Doubly-fed induction generator with rotor-side converter

Search WWH ::

Custom Search