Environmental Engineering Reference

In-Depth Information

Filled with

Water

Free Water

Evacuation

Apply

Suction/

Pumping

pumps

pumps

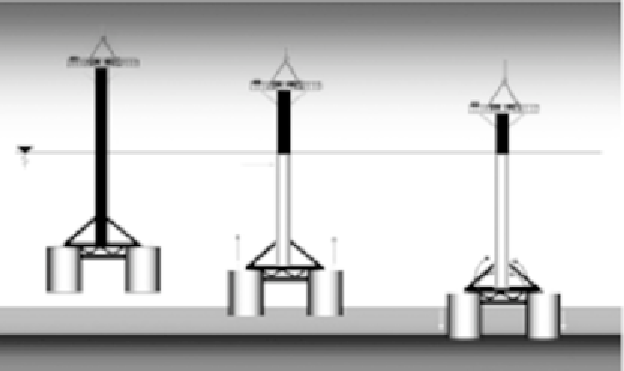

Vertical Flotation Before Touchdown

Self-Weight Penetration

Suction Penetration

FIGURE 2-5

Installation of a suction caisson foundation.

Suction caissons

are inverted buckets that initially are settled partially into the seabed by the

weight of the platform and then are pulled deeper by suction created when

water is pumped out of the top of the caisson. (S

OURCE

: http://www.

power-technology.com/projects/hk-windfarm/hk-windfarm2.html.)

special installation vessels and equipment for driving the pile into the

seabed and lifting the turbine and tower sections into place.

Suction caissons can be alternatives to driven piles, eliminating the

intense underwater hammering noise that is a concern for marine mam-

mals. Large-diameter suction caissons can be welded to the base of a

monopile, in which case they often are referred to as “mono-bucket” foun-

dations. Smaller-diameter suction caissons can be used in place of slender

piles to pin jacket substructures to the sea floor. Medium-diameter suc-

tion caissons can be used in place of piles to pin tripods to the sea floor, as

shown in Figure 2.5.

Approximately 20 percent of offshore installed wind turbines are on

reinforced concrete gravity-base foundations, which avoid the need to use

a large pile-driving hammer and instead rely on mass and a larger base

dimension to provide stability and resist overturning. Gravity-base systems

require a significant amount of bottom preparation before installation and

are compatible only with firm soil substrates in relatively shallow waters.

For water depths of 30 m to 60 m (98 ft to 197 ft), which are considered

“transitional depths” between fixed and floating substructures, monopile

Search WWH ::

Custom Search