Environmental Engineering Reference

In-Depth Information

2000

T

f

max

1500

T

out

1000

T

in

1

T

f

max

= 1600 C

500

ζ

= 0.1

m

α

= 0.95

0

0

1

2

3

4

5

6

Gas recirculation ratio, R ( m / m )

rec

in

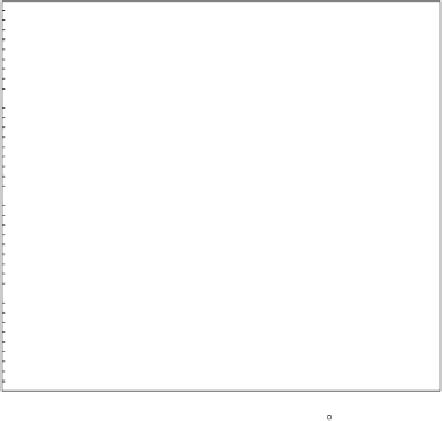

FIGURE 2.31

Superimposed contour map of the maximum combustion gas temperature and

the temperature affected by gas recirculation and heat recirculation.

is remarkably small compared with conventional furnaces. Both

T

fmax

and ∆

T

distri-

butions were then superimposed in

Figure 2.31

.

Here the contour lines are shown of

∆

T

for every 50˚C in the range from 100 to 300˚C. The results show that an increase

of both heat recirculation by air preheat and gas recirculation results in decrease of

flame temperature and also decrease of the temperature difference between the flame

and the flame gas.

2.2.4.3.3 Thermal Efficiency

The operation to increase heat and gas recirculation while maintaining the maximum

flame temperature can be performed as shown in

Figure 2.32

,

where

T

fmax

,

T

out

and

decay resulting from the effect of dilution due to the combustion gas recirculation.

The temperature difference, ∆

T

, becomes noticeably smaller and

T

out

becomes grad-

ually closer to

T

fmax

. The thermal efficiency in this condition was calculated and the

result is shown in

Figure 2.33

. I

t revealed that this operation can increase the thermal

efficiency as well as improving the temperature difference, ∆

T

.

2.2.4.4 Discussion

The method of additional enthalpy combustion has been generally interpreted to be

an effective way to enhance the thermal field in furnaces for increasing the heat

transfer rate. The excessive increase of the maximum flame temperature, however,

is a major problem causing overheating of materials in the furnaces. The result

obtained here, as shown in Figure 2.33, revealed that high temperature additional

Search WWH ::

Custom Search