Environmental Engineering Reference

In-Depth Information

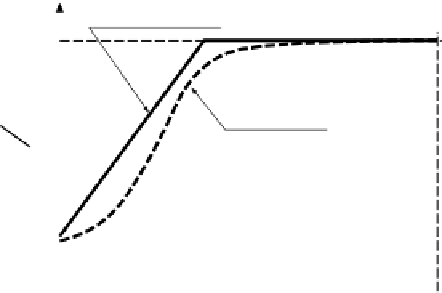

Modeled Pattern

r

2

Real Pattern

r

1

0.0

τ

1.0

Normalized material residence time in furnace

1

1

(

)

()

=

∫

(

)

∫

()

fr

fr t dt CT

=

3

1

+

r

+

r

2

+

r dt

3

(2.9)

T

T

r

out

T

T

T

0

0

The range of the integration of the

Figure 2.25

is given when integral variable

t

is converted to

r

T

. The temperature of the combustion gas at the furnace entrance,

T

gin

, is assumed to be the maximum temperature of the gas,

T

fmax

, and the temperature

at the furnace exit

T

gout

as

T

out

.

T

T

T

T

T

T

T

T

m

m

m

m

r

==

,

r

= =

in

in

out

out

1

2

g

f

g

f

in

max

out

max

The temperature of the heated material at the furnace exit can be given by using

the heat quantity of the heated materials.

Tm

Q

Cm

T

=

+

(

m

(2.10)

)

m

in

˙

out

m

The amount of convection heat transfer gained by the heated materials is given

by Equation 2.10 obtained by treating the convective heating process as a parallel

flow type of heat exchanger.

(

)

=

(

)

(

)

˙

Q

1-

ξ

Cm

T

−

T

conv

m

m

mix

m

in

{

}

(

{

}

=

(

)

+

(

)

)

+

(

)

T

CmT

˙

CmT

˙

Cm

˙

Cm

˙

(2.11)

mix

in

f

in

m

in

m

max

in

(

)

ξ

=

exp -

bKL

m

m

m

m

Search WWH ::

Custom Search