Environmental Engineering Reference

In-Depth Information

heat release rate in the furnace as well as on the resultant temperature distribution.

We consider the heat transfer in furnaces from this point of view.

To realize the effective heat transfer in HiTAC furnaces, discussion is required

on each mode of heat transfer (conduction, convection, and radiation). Among these,

conduction from flames to the materials being heated is not so important when we

consider the heat transfer in furnaces, although conduction is important when we

discuss the depth of heating in the material. Thus, it is enough if conduction is taken

into consideration only when the loss through furnace walls is discussed.

1.2.3.1 Convection Heat Transfer of High Temperature Air

Combustion

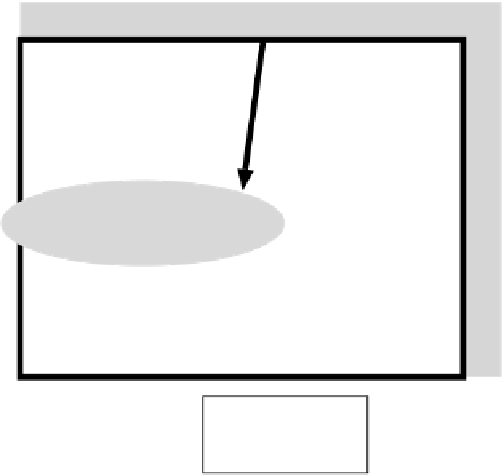

The heat transfer in a conventional industrial furnace can be described in the sche-

matic diagram shown in

Figure 1.9

.

The convection heat transfer comprises a very

small proportion of the total heat transfer rate from combustion gas to the material

being heated. The heat convection rate is expressed by the product of heat transfer

coefficient, contact area, and the temperature difference between the solid surface

and its adjacent gas. The characteristic length of convection heat transfer depends

on the boundary layer thickness. If there is a large deviation in the spatial distribution

of temperature in combustion gases, the local convection heat transfer will generate

nonuniform heat flux onto the material, and hence the temperature distribution on

the surface. The redistribution of heat will follow by way of radiation and conduction,

which will take somewhat longer.

Wall

Gas in Furnace

direct contact

Material

FIGURE 1.9

Heat transfer in furnaces.

Search WWH ::

Custom Search