Environmental Engineering Reference

In-Depth Information

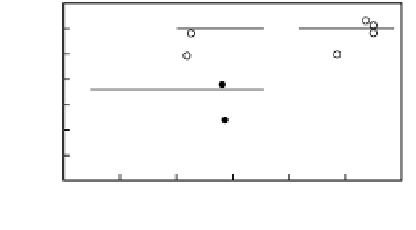

90

90%

80

Adoption of high performance

industrial furnace

78%

70

with air preheater

without air preheater

60

0

5

10

15

20

25

30

Combustion heat amount ( 10

6

kcal/h)

FIGURE A.10

Fuel consumption and heat efficiency in petroleum heating furnaces.

According to the most recent data (in 1993) of the Petroleum Federation on petro-

leum heating furnaces, the number of furnaces, 832, and the energy consumption,

7.74

10

9

l/year (converted crude oil), can be used for calculations.

×

4. Industrial boiler

The results of the development can also be applied to industrial boilers. Although

the number of and energy consumption of industrial boilers is not confirmed in this

investigation, the data on the number of boilers, 32,350, and the energy consumption,

38,028

10

6

l/year, from the data of the Agency of Natural Resources and Energy

in 1975, are used for the calculation from the viewpoint of using the minimum values.

Industrial boilers are generally water tube type, where 80% heat efficiency can

be obtained even in small-scale furnaces and 90% in large-scale furnaces owing to

heat recovery of waste heat by means of an economizer or air preheater. Conse-

quently, if the current heat efficiency of industrial boilers is 85% on average, the

value of 90% heat efficiency could be achieved, as with petroleum heating furnaces.

×

A.5.2 R

ESULTS

OF

THE

C

ALCULATION

The summary of the assumptions and the results of the calculations are shown in

Table A.11

.

The following points have been clarified:

1.

The number of facilities for objects:

N

industrial furnaces

N

=

32 767

,

+

32 350

,

=

65 117

,

~

65 000

,

industrial boilers

2.

The energy consumption for objects:

E

(l/year)

industrial furnaces

E

=

48 75

.

×

10

9

+

38 02

.

×

10

9

=

86 77

.

×

10

9

~

87

×

10

9

industrial boilers

Search WWH ::

Custom Search