Environmental Engineering Reference

In-Depth Information

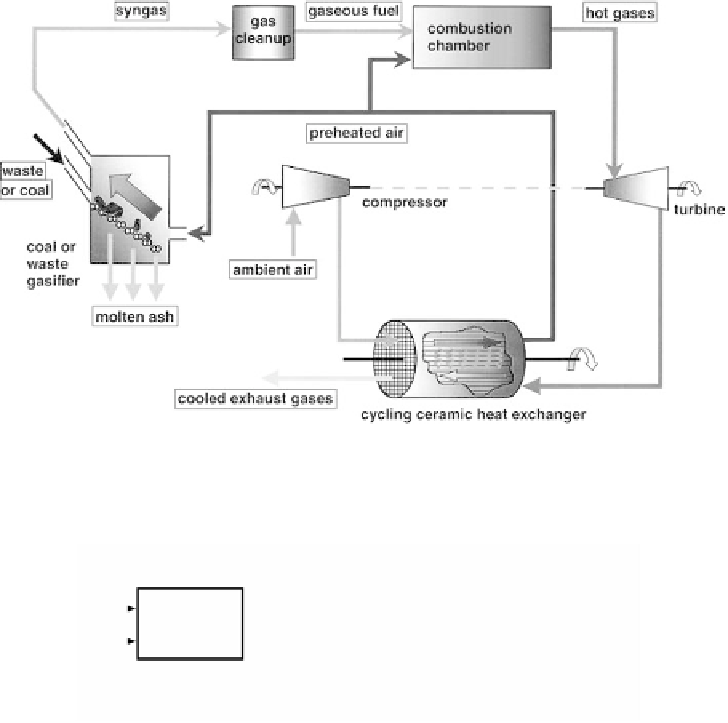

FIGURE 6.5

A schematic diagram of high temperature w

aste gasification and industrial gas

turbine system.

Product

Raw

Material

Steam

Waste

Syngas

Boiler or

Power

Generator

Gasification

of Waste

Production

Facility

Energy

Electricity

High

Temp. Air

High Temp.

Slag (Useful for road

bed construction)

FIGURE 6.6

Prospects for future ultra-lo

w waste generation from a production facility.

P

art of the energy in the syngas may be used for high temperature air/steam pre-

heating and the remainder may be used for power generation, steam generation, and

industrial heating. With a proper design various undesirable constituents in the waste

can be recovered, such as heavy metals (Fe, Cu, Al), inorganic compounds in the

form of nonleachable slag, and sulfur and chlorine.

The proof of concept for the

overall process shown in

Figure 6.7

requires validation. The main features of this

waste-to-energy conversion are as follows:

5

1. Conversion of solid wastes and low grade fuels (including coals and high-

moisture-containing municipal and industrial wastes) to clean gaseous fuels

having low to medium calorific value. The composition of the gaseous fuel

can be adjusted via some control of the chemistry, e.g., gasification, pyrol-

ysis, or reforming of the waste with steam and high temperature air, thus

increasing the calorific value of the gases produced.

Search WWH ::

Custom Search