Environmental Engineering Reference

In-Depth Information

Syngas

High Temperature

Air

Solid Waste

Waste Material

Fixed grate

Syngas

Slag

High Temperature

Air

FIGURE 6.3

A schematic diagram of twin chamber “bed type” g

asifier.

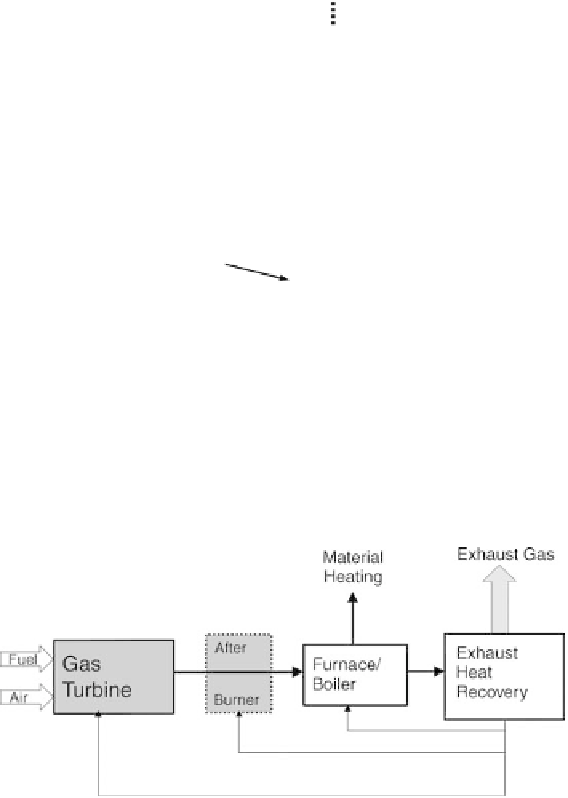

FIGURE 6.4

A schematic diagram of industrial g

as turbine and furnace.

produced; see

Figure 6.6

.

Of course, this is an ideal representation for a plant with

the aim to stimulate and challenge engineers on the design of future facilities.

Much of what has been discussed so far involves the transformation of waste to

syngas chemical energy in only one stage in the bed. A gasifying agent can be used

to improve the calorific value of the gas produced. One such agent includes steam

but another suitable gas can also be used. A schematic diagram of the steam-assisted

gasification system is shown in

Figure 6.7

.

The objective of the gasifying material

is to further enhance the conversion of carbon in the waste (fuel) to syngas fuel.

The syngas evolved can also be used for power generation, using, for example, high

temperature air principles in micro gas turbines. Typical mole fraction of the steam

in air in Figure 6.7 would be 10 to 20%, depending on the properties of the fuel.

Search WWH ::

Custom Search