Environmental Engineering Reference

In-Depth Information

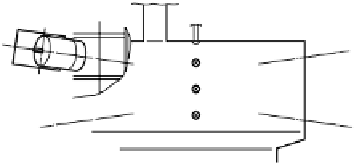

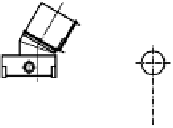

Regenerative burner

Door lifting device

Charging door

Exhaust gas duct

M.L

M.L

Dross chute

Metal discharge mouth

Porous plug

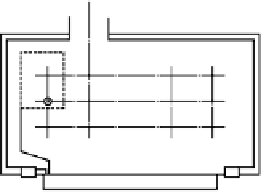

FIGURE 5.79

High performance aluminum-melting furnace.

5.5

FIELD TRIALS AND EXPERIENCES OBTAINED

THROUGH FIELD TEST DEMONSTRATION PROJECT

The Third Conference of Parties on the Framework Convention on Climate Change

(Kyoto Conference on the Prevention of Global Warming, COP3) was held in

December, 1997, and the “Kyoto Protocol” was adopted. This protocol stipulated

that Japan should achieve more than 6% reduction of greenhouse gases from the

1990 emission level within the period from 2008 to 2012. To meet the target, it was

considered crucial to reduce the total amount of energy consumed by the industrial

sector, which accounts for about 50% of total energy consumption in Japan. Various

industries, in particular the iron and steel industry, which uses industrial furnaces,

and the petrochemical industry, were expected to work toward achieving energy

saving.

Under these circumstances, one part of the research and development of the

High Performance Industrial Furnace Development

project, which had been pro-

moted from 1993 by NEDO, was completed in 1998. The project resulted in tech-

nological advances including new technologies applicable to energy saving purposes.

MITI and NEDO initiated a joint research program called High Performance Indus-

trial Furnace Field Test Demonstration Project for a period of 3 years from 1998 to

2000 as a step toward the practical application of the technology on the basis of the

results of the development project mentioned above.

3

This program is now under way.

This section details facts related to the program and the data, although partial,

obtained from the program to the end of 1998. In addition, information on the

applications for the field test in fiscal year 1999 is included. The project aims to

Search WWH ::

Custom Search