Environmental Engineering Reference

In-Depth Information

1

0.39

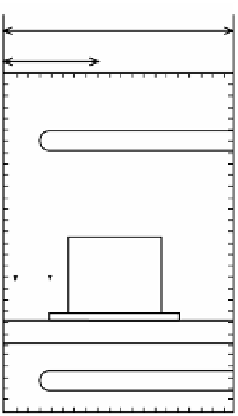

FIGURE 5.76

Distribution of wind rate generated by fan.

Inside width

of furnace

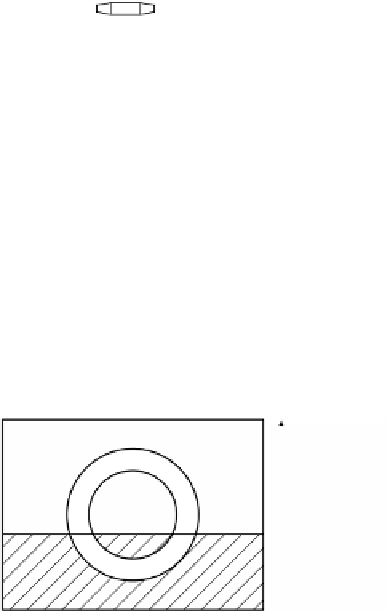

FIGURE 5.77

Region of “down blowing” in furnace.

g. Calculation of heating and cooling: calculation of heating and cooling

can be conducted by using φ

CH

of surface of coils and the heat con-

duction coefficient of inside coils. In this case, the calculation of

discrete differential equation of heat conduction can be done on a

personal computer. Details can be seen in the paper “The Method of

Numerical Calculation of Non-stable Heat Conduction” (The Iron and

Steel Institute of Japan).

5.4.4

M

ELTING

F

URNACE

5.4.4.1

Energy Savings and Exhaust Gas Regulation

It is required that the fuel used for aluminum-melting furnaces be cost-effective, and

often oil such as heavy oil Type A is used. Aluminum-melting furnaces are batch-

operated, and the temperature inside the furnace is raised from 700˚C to approxi-

mately 1150˚C, when the melting of aluminum starts. As a means of recovering

Search WWH ::

Custom Search