Environmental Engineering Reference

In-Depth Information

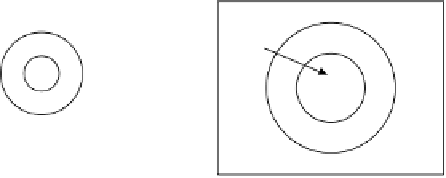

Coil

diameter D2

Coil

diameter D1

Furnace

width W1

Furnace

width W2

Test furnace

High performance heat treatment furnace

FIGURE 5.71

Test furnace and high performance heat treatment furnace.

The heat transfer coefficient in the furnace consists of six parameters, as shown

in Equation 5.7:

α =

f

(

L

,

V

, ρ , µ, λ ,

C

p

)

(5.7)

where

L

= key length

ρ

= density of liquid

= heat conductivity

V

= average flow rate

µ

= viscosity of liquid

C

p

= average specific heat of liquid

The dimension analysis of Equation 5.7 by the Buckingham

theorem provides that

the parameters are 6 - 3 = 3. Consequently the well-known nondimensional control

equation of convective heat transfer can be obtained as the following expression:

Nu =

f

(Re, Pr)

(5.8)

The nondimensional control equation for two furnaces can be maintained equal by

applying Equation 5.9:

12

13

Nu

x

= 033

.

Re r

(5.9)

3. To derive the nondimensional boundary conditions

From Equation 5.8, Nusselt numbers Nu can be maintained equal by combining the

values of Reynolds number Re and Prandtl number Pr between the two systems. In

this, Pr of these systems can be maintained equal under the same kind of gas, because

all the parameters are determined by the kind of atmospheric gas. If the values of

the Re of the two systems are the same, then the conditions mentioned above to

realize the rule of similarity on heat transfer in furnaces are satisfied.

From the following relation, the average diameter of coil in the test furnace

D

= 1.37

m and the average flow velocity around the coil in the test furnace

V

= 3.36

m/s, we can obtain the following relation:

ρ

VD

4

Re

=

=

30 8

.

×

10

1

µ

Search WWH ::

Custom Search