Environmental Engineering Reference

In-Depth Information

Recirculation Ratio

0

0.5

1

1.5

2

345

OO

Re = 1.2 10

3

Re = 4.2 10

3

1800

air

fuel

1600

Stable Region

(combustible by auto- and forced-ignition)

1400

auto-ignition limit

1200

1000

forced-ignition limit

800

Noncombustible Region

Blow-off (forced-ignition)

600

Unstable Point (CO < 100 ppm)

Auto-ignition Temperature

(diluted by N

2

or CO

2

)

400

20

15

10

5

0

O

2

concentration, %

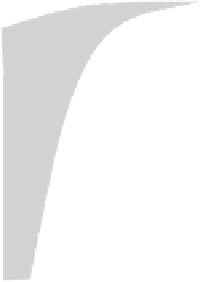

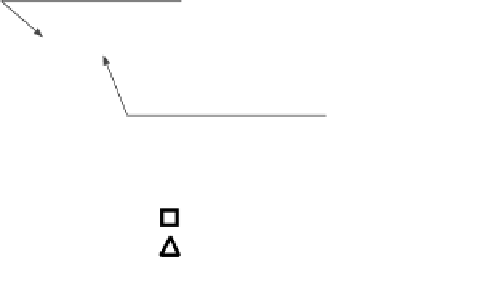

FIGURE 1.4

auto-ignition limits and blow-off limits of propane in a preheated air or a diluted

air with nitrogen.

temperature of the fuel. Actually, very diluted air, whose oxygen concentration is as

low as 3%, can sustain combustion when it is preheated up to 1200 K.

Hasegawa et al.

14

discussed the individual and multiple influences of heat and

gas recycling. In

Chapter 2

,

Figure 2.29

shows contours of the maximum flame

temperature on the combined effect of preheated air temperature and recycling rate

of burned gases, where

R

is the gas recycling rate. A combination of highly preheated

air and high recycling rate of burned product generates relatively low maximum

flame temperature. One can understand that the stoichiometric flame temperature in

very diluted air, where mass fraction of oxygen is far below the value in normal

atmospheric air, is not as high as is usually expected. This is the key for HiTAC

when it is applied to practical combustion systems. Keeping the global equivalence

ratio constant, the flame temperature in the furnace can be varied or regulated by

combining the preheated air temperature and the recycling rate of burned gases.

The concept of the HiTAC is illustrated in

Figure 1.5

,

compared with that of a

conventional furnace combustion. Extremely high temperature flames are usually

Search WWH ::

Custom Search