Environmental Engineering Reference

In-Depth Information

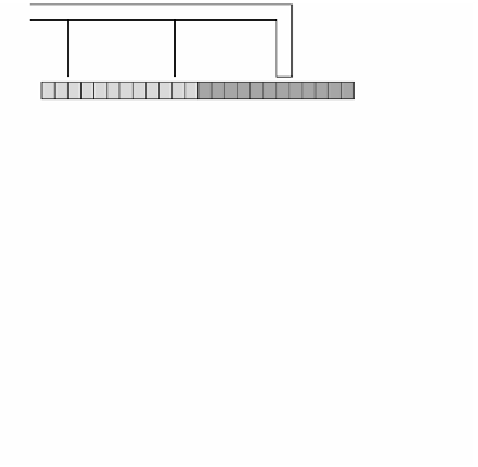

zone (N-1)

zone N

Furnace discharging

port (Outlet)

Lot (X+1)

Lot X

Discharged Steel workpiece

Steel workpiece

charging direction

Operating

conditions

Temperature of discharged

steel workpiece

Actually

measured value

:

Set value

Lot X

Lot (X+1)

Time

Condition-change time (X X+1)

Soaking level of discharged steel workpiece

FIGURE 5.59

Schedule-free heating.

The interface function collects the information required for the online model of

the online tracking function such as the temperature of the steel workpiece and

furnace temperature obtained from a continuous heating furnace at fixed intervals.

It also passes the optimum furnace temperature set values obtained by the online

optimum heat pattern calculation function to the furnace temperature control function

at fixed control intervals.

The furnace temperature control function determines the amount of fuel to be

supplied in such a manner that the optimum furnace temperature set value is

maintained. The operation monitor screen starts, stops, or displays the status of the

functions of the digital control system that was actually used in this study.

In an online model, the imbalance portion of the heat balance of the in-furnace

gas is calculated to determine the change in the enthalpy. The radiant heat flux is

determined using the total absorptivity method (φ

CG

method). The temperature dis-

tribution in a steel workpiece is calculated by dividing the workpiece in the thickness

direction and using the difference calculation method. The distribution in the feeding

direction is calculated for each workpiece independently. The radiative heat transfer

and convective heat transfer from the gas to the surface of the workpiece that is in

contact with the gas and a certain amount of heat loss caused at the bottom of the

workpiece must be taken into consideration. For heat transfer through the furnace

wall, the furnace wall and ceiling are considered a single entity in the calculation

of heat transfer. As in the case of the steel workpiece, the temperature distribution

on the wall is calculated by dividing the wall in the thickness direction and using

the difference calculation method. The model calculation is made at fixed time

intervals. With calculation for the movement time equivalent to the mesh width in

Search WWH ::

Custom Search