Environmental Engineering Reference

In-Depth Information

Company

A

B

C

Actual fuel consumption, Mcal/ton

250-25

9

22

5

24

2

Calculated results, Mcal/ton

259

22

4

23

8

32000

30000

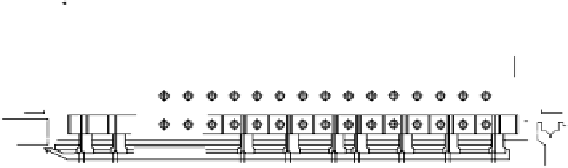

FIGURE 5.40

High performance reheating furnace for slabs of 285 ton/h (unit = mm).

40000

38000

FIGURE 5.41

Conventional reheating furnace for slabs of 285 ton/h (unit = mm).

heat recovery rate is at its maximum for each heating value.

Figure 5.49

is a graph

obtained by choosing the specific point in

Figure 5.48

of the furnace length =

30 m.

The tendency for the fuel consumption to increase with a decrease of the calorific

value is also seen with the ratio of exhaust gas volume/air shown in

Figure 5.47

.

This is caused by the difference in exhaust gas volume.

The air ratio also has a large effect on the fuel consumption. The effect was

studied on a reheating furnace for slabs of 250 ton/h. Five factors were studied in

combination, and the results of these studies are shown in

Figure 5.50

.

These factors

are the effect of air ratio, furnace length, heat-recovery rates, charging and discharg-

ing temperatures, processing capacity, ton/h, and the slab thickness.

Search WWH ::

Custom Search