Environmental Engineering Reference

In-Depth Information

auto-ignition. In contrast, if a fuel of lo

w calorific value is adopted, the combustible

domain disappears at ambient temperature and reappears when the mixture is pre-

heated over a certain temperature level, as shown in the figure exhibiting conceptual

trends.

Most of the previous research in this field has been aimed at burning ultra-lean

mixtures or low calorific value fuels produced in chemical processes or vented from

coal mines. In those cases the resultant maximum flame temperature with heat

recirculation was not crucial to the tolerance of materials used in the system because

of the low calorific value. Further, scientific studies on heat recirculating combustion

have been mostly carried out on relatively small-scale premixed flames. However,

for large-scale industrial use, diffusion or non-premixed combustion is more common

because of its controllability and safety. Heat recirculating combustion in diffusion

or non-premixed combustion can be achieved by heating combustion air with the

recycled heat from burned products. The temperature of combustion air in an adia-

batic system can theoretically be raised to almost the same temperature as the exhaust

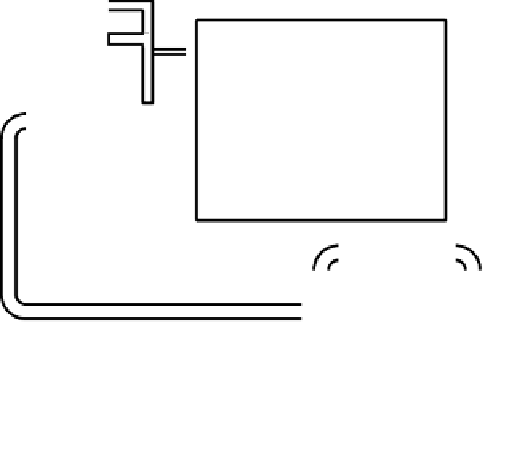

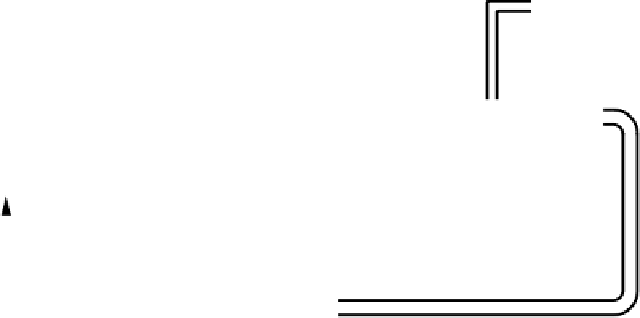

stream by regenerative heat exchangers. In practice, the regenerative combustion

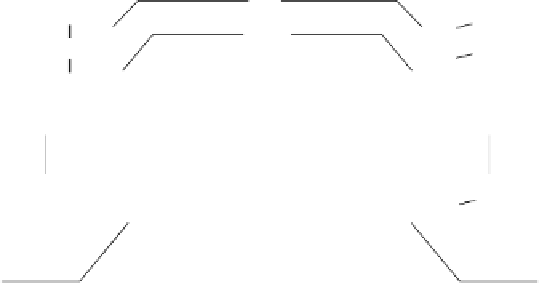

system for implementing high temperature air combustion is the system shown in

Figure 1.3

,

where a heat recirculating method (by use of honeycomb-type regener-

ators) is applied to a heating furnace. A pair of burners, operating alternately, is used

as a unit and the flow path for air ejection in each burner is filled with ceramic

Pilot burner A

Pilot burner B

Spark Plug A

Spark Plug B

Air

Air

Fuel

Fuel

open

close

Flow and combustion

Heat transfer

Fuel

Slab

Fuel

open

close

Burner A

Burner B

4-way switching valve

Insulation

Air

Exhaust gas

Ceramic Honeycomb

FIGURE 1.3

Schematic diagram of HiTAC furnace operated with high frequency alternating

flow regenerators.

Search WWH ::

Custom Search