Environmental Engineering Reference

In-Depth Information

70

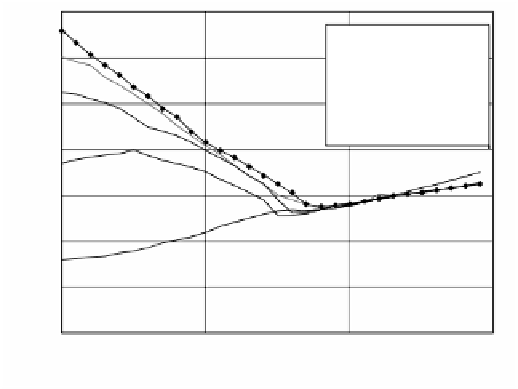

Rimmed steel

3.5% Ni steel

Killed steel

18-8 stainless steel

Low-carbon steel

60

50

40

30

20

10

0

0

500

1000

1500

Temperature,

°

C

FIGURE 5.35

Examples of the relationship between steel temperature and thermal

conductivity.

5.2.3 C

ALCULATION

OF

P

REHEATED

A

IR

T

EMPERATURES

AND

E

XHAUST

G

AS

T

EMPERATURES

AFTER

H

EAT

E

XCHANGE

The regenerative heat exchanger simulator carries out a non-steady convergence

calculation requiring extensive computing time. It should also be noted that reheating

furnaces have multiple regenerative heat exchangers and it is very difficult to do the

calculation combining all the exchangers. Therefore the present reheating furnace

simulator does the calculation using as input data the heat recovery rates of heat

exchangers obtained by the regenerative heat exchanger simulator. Air and the

specific heat of exhaust gas are the nonlinear functions of temperatures. Therefore,

a simple multiplication of the exhaust gas temperature by the heat recovery rate does

not give the correct temperature of the preheated air.

As

Figure 5.36

shows, (a) the sensible heat of exhaust gas is obtained from the

exhaust gas temperature, and (b) the sensible heat of the preheated air is obtained

from the heat recovery rate from this sensible heat of exhaust gas. Next, (c) the

preheated air temperature is obtained from the sensible heat of the preheated air

where a convergence calculation is also carried out to obtain the heat balance, taking

into consideration also the condition that the exhaust gas temperature is greater than

the preheated air temperature. This method is applied both to regenerative heat

exchangers and to recuperators.

5.2.4 R

ADIATION

H

EAT

FROM

THE

F

URNACE

B

ODY

AND

H

EAT

L

OSS

BY

C

OOLING

W

ATER

The radiation heat from the furnace body of this zone (I) is calculated by Formula

5.1. The temperature simulator is programmed in the form of a box to simplify its

Search WWH ::

Custom Search