Environmental Engineering Reference

In-Depth Information

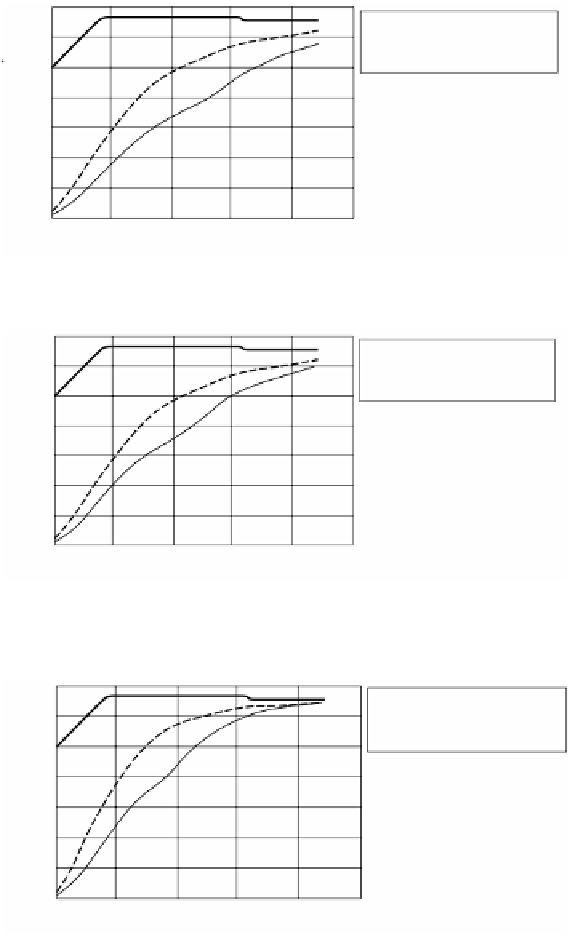

infinite column (round billets), and two-dimensional infinite plate (billets). As shown

in

Figures 5.30

to

5.32

,

the heating curve varies significantly depending on the steel

form. Therefore, when inputting data, an appropriate form is selected as an approx-

imation, based on which the calculation is carried out. Temperatures along the

furnace length are obtained by calculating the temperature for each location of the

steel, converting the location to time.

1400

Upper furnace temperature

Top surface

Center

Slab size 200mm thick x 2000mm width

Reheating tonnage 200 ton/h

φ

CG

= 0.7

1200

1000

800

600

400

200

0

0

5

10

15

20

25

Furnace length, m

FIGURE 5.30

Slab temperature increase with furnace length.

1400

Upper furnace temperature

Top surface

Center

Bloom size 200mm thick x 200mm width

Reheating tonnage 200 ton/h

φ

CG

= 0.7

1200

1000

800

600

400

200

0

0

5

10

15

20

25

Furnace length, m

FIGURE 5.31

Square bloom temperature increase with furnace length.

1400

Upper furnace temperature

Top surface

Center

Billet diameter 200mm

Reheating tonnage 200 ton/h

φ

CG

= 0.7

1200

1000

800

600

400

200

0

0

5

10

15

20

25

Furnace length, m

FIGURE 5.32

Round billet temperature increase with furnace length.

Search WWH ::

Custom Search