Environmental Engineering Reference

In-Depth Information

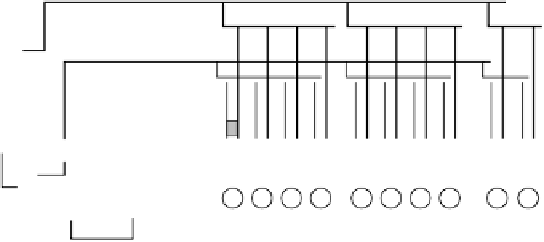

Combustion air

Exhaust gas 1

Thermal storage media

Steel

discharging

side

Steel

charging side

1

Non-combustion zone

2

Preheating zone

3

Heating zone

4

Soaking zone

Skids

Exhaust gas 2

FIGURE 5.27

Continuous reheating furnace for semifinished steel with regenerative heat

exchangers.

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

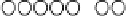

(C) Air/gas flow system

(A) Air/gas flow system

1400

1400

1200

1200

1000

1000

800

800

600

600

Upper furnace temperature

Top surface

Center

Backside surface

Upper furnace temperature

Top surface

Center

Backside surface

400

400

200

200

0

0

0

10

20

30

0

10

20

30

40

Furnace length, m

Furnace length, m

(B) Distribution of temperature of steel

(D) Distribution of temperature of steel

FIGURE 5.28

Distributions of temperature of steel in a conventional furnace (C, D) and a

high performance furnace (A, B) with air/gas flow systems.

For the basic functions of the simulator, it was also decided that the simulator

would be a process simulator for studying such characteristics of a reheating furnace

as fuel consumption and required furnace length. It was then necessary to obtain

the temperature of steel in the furnace and to observe the effects of varying other

parameters. For calculation method and input data, the simulator is a simplified

model and basic data are input to carry out the calculations. The furnace size, zone

length, furnace height, and furnace width serve as one factor. The simulator calcu-

lates the heat balance (

Figure 5.29

)

and the following are input as operational

conditions required for the calculation:

Search WWH ::

Custom Search