Environmental Engineering Reference

In-Depth Information

8000

Approximate

Actual1

Actual2

Actual3

Imaginary Cap.

CFD

7000

6000

5000

4000

3000

2000

1000

0

0

2

4

6

8

10

12

14

Furnace width, m

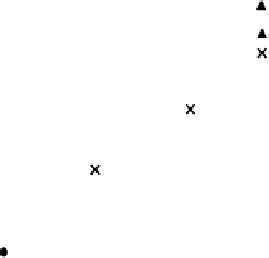

FIGURE 5.26

The relationship between furnace width and maximum combustion capacity.

balance model. Further, when selecting larger-capacity burners than this index to a

given furnace width such as the point of Actual3 in

Figure 5.26

,

counter-measures

can be adopted to avoid the problem as the burner design concept is changed.

5.2 HEAT BALANCE AND PERFORMANCE

ESTIMATION WITH SIMULATION PROGRAM

5.2.1 O

UTLINE

OF

S

IMULATION

P

ROGRAM

Recently, many high performance industrial furnaces (regenerative furnaces) that use

regenerative heating exchangers have been developed. These furnaces are replacing

conventional reheating furnaces that use recuperators (conventional furnaces). Com-

parison between the high performance industrial furnaces and the conventional fur-

naces in the case of continuous reheating furnaces for semifinished steel (billets, slabs,

etc.) shows a big difference not only in combustion air and the flow of exhaust gas,

this is true, future designs for saving energy will have to be reconsidered.

For this purpose, it is necessary to make a comparative evaluation of high

performance furnaces with regenerative heating exchangers and conventional fur-

naces with recuperators

(

Figure 5.28

)

. It then becomes necessary to quantify the

relationship among factors including fuel consumption and heat recovery rates,

discharging temperatures, processing mass capacities (ton/h), size of steels to be

reheated, and charging temperatures. Therefore, a simulator was developed to eval-

uate the performance of the two types of reheating furnaces: those with regenerative

heat exchangers and recuperators. This would also be useful when drawing up basic

plans for the furnaces.

Search WWH ::

Custom Search