Environmental Engineering Reference

In-Depth Information

1400

F1 Mode

F2 Mode

1200

1000

Heat input (including the sensible heat of air)

:930kW (800,000kcal/h) constant

800

Furnace temperature

(Normal temperature air)

Steel average

(Normal temperature air)

600

400

Furnace temperature

(High temperature air)

Steel average

(High temperature air)

200

197min.

238min.

0

0

50

100

150

200

250

300

350

Time, min.

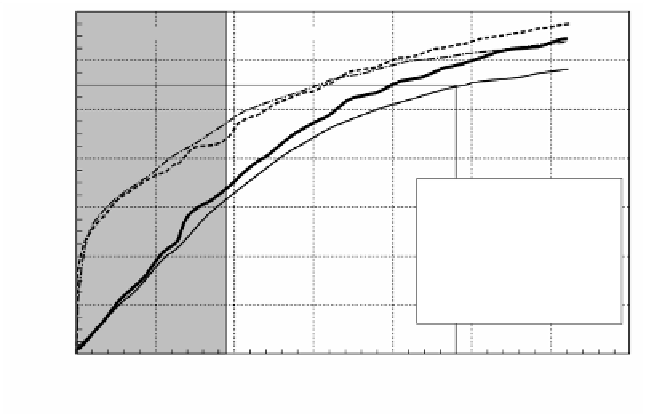

FIGURE 5.18

Comparison of the rate of temperature rise under the constant heat input of

930 kW.

400

Ts3,max-Ts2,min (High temperature air)

Ts3,max-Ts2,min (Normal temperature air)

350

300

Ts3

Ts2

Ts1

250

200

Flame

150

100

50

0

0

50

100

150

200

250

300

350

400

Heating time, min.

FIGURE 5.19

Change of steel surface temperature with time.

1. Effect of flame locations

To change the locations where the flames were formed, combustion in the direction

of the furnace width (burners C, D, E, and F) was established so that the flames

were formed beneath the skids. As a result, the steel temperature near the skids rose

even under normal combustion, and the ion current that shows the existence of flames

also increased, but ∆

T

was larger compared with that of the combustion with high

temperature air (

Figures 5.21

and

5.22

).

To enhance the dilution of air jet by the

Search WWH ::

Custom Search