Environmental Engineering Reference

In-Depth Information

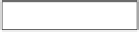

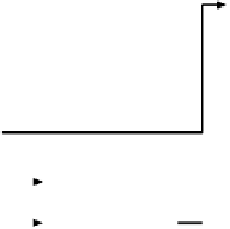

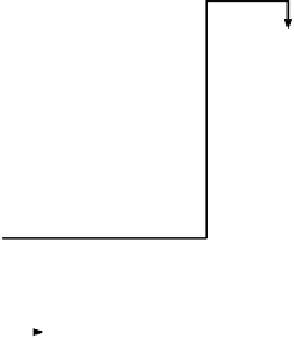

T

ABLE 5.2

High Performance Furnace Design Flow

Database

Restrictions

Basic design

Optimum shape of furnace

In-furnace width database

Heating capacity ton/h

Furnace width

Shape of object to be

heated

Charging and discharging

temperatures

Arrangement of support

beams

Furnace length

Soaking level (Temperature

distribution on discharged

sample)

Product mix

Furnace bed load database

In-furnace height database

Effective furnace length

Furnace height

Maintainability

Positions of furnace and

equipment placed in front of

and behind the furnace

Treatment method of

exhaust gas of combustion

Energy saving measures

and downsizing of furnace

and peripheral equipment

In-furnace transportation

system (hydraulic system,

electric motor system)

Permissible skid mark

Position of outlet and

direction of exhaust

Configuration of refractory

material in the furnace body

In-furnace heat transfer

calculation

Basic design plan 1

Standard material and product

mix ton/h

Determination of furnace type

Provisional determination of

furnace bed load

Provisional determination of

heat pattern

Consideration of emissivity of

object to be heated

Determination of effective

furnace length

Determination of furnace

dimensions (length, width and

height)

Determination of zone division

Determination of type and

layout of burners

Selection of optimum regenerator

CG

and preheated air

temperature database

Shape, dimensions, and

material of support beam

button

Skid mark database

Outer wall heat release

database

W.B. mechanism

Shape and dimensions of

inlet and outlet

Position of outlet and

direction of exhaust

Heat balance database

Scale treatment method on

furnace bed and water-

seal trough

Suitable burner

Type of fuel

In-furnace heat transfer

calculation

Temperature distribution in

furnace-width direction

NOx regulations

Components of combustion

gas (CO/CO

2

, H

2

/H

2

O)

Inspection for harmful

substances (CO, SOx,

smoke and soot)

Maximum and minimum

combustion rate of burner

and shape of flame

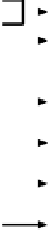

Basic design plan 2

Integration of heat balance in

each zone and confirmation

of results

Estimation of the flow of in-

furnace gas and in-furnace

temperature distribution

Determination of type,

number, capacity of burners

Determination of capacity

and number of burners in

each zone

Determination of combustion

rate in each zone

Grouping of burners in each

zone and grouping of

piping

Selection of optimum

regenerator

Basic design plan 3

Determination of blower capacity

Determination of exhaust fan

Determination of smoke stack

draught (diameter, height)

Pressure control database

Temperature control

database

Selection of temperature

control level

Control system

Determination of fuel unit

consumption

Determination of cooling water

quantity

Confirmation of types of utilities

Determination of burner

turndown ratio and c.v.

diameter

Furnace pressure control

Limit of air penetration

O

2

control

Instrumentation plan

Flow rate control

Exhaust gas temperature

control at regenerator outlet

Preparation of control diagram

(Power, heat transfer, tempera-

ture control, flow rate control,

pressure control, safety device)

Preparation of utility system

diagram

Safety standard

Emergency measures

Safety measures

Preparation of operation plan

Combustion safety device

High performance furnace

Search WWH ::

Custom Search