Environmental Engineering Reference

In-Depth Information

2500

O

2

=7%

7%

1%

2000

High temperature air combustion

Preheated air temperature =1600 K

1600 K

1500

Conventional combustion

1200 K

1000

burner

end

Distance from burner

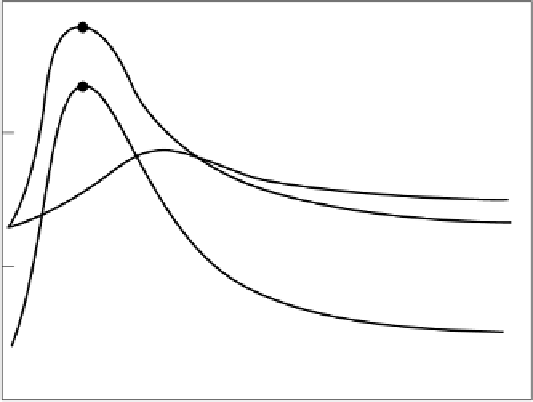

FIGURE 4.18

Oxygen concentration at peak point and distribution of temperature of flame

on burner center axis.

that of conventional combustion at 1200 K. It proves that the peak temperature in

high temperature air combustion can be controlled even if the preheated air temper-

ature is raised. Further, since the oxygen concentration at the peak point is much

lower than that in the conventional combustion, it is possible to realize low NO

x

combustion in high temperature air combustion.

4.3.2 R

ESULTS

OF

THE

T

EST

ature, preheated air temperature, and exhaust gas temperature of the exhaust gas

obtained from the combustion test executed in the common test facility II. The

furnace temperature was measured by a thermocouple at 100 mm below the furnace

ceiling. Note that the preheated air temperature was lower than the furnace tem-

perature by only 50 K. Using such high temperature combustion air, NO

x

concen-

tration as low as 90 ppm (not converted) resulted. This value is less than 1/3 of

NO

x

concentration in a conventional low NO

x

b

urner and less than 1/10 of that in

a quick-mixing type burner, thus marking a large NO

x

reduction in high temper-

ature air combustion. The time-based variations in the preheated air temperature,

exhaust gas temperature, and NO

x

concentration were caused as a result of the

change of combustion behavior of a regenerative burner combustion system using

the burner switching time intervals of 30 s.

Search WWH ::

Custom Search