Environmental Engineering Reference

In-Depth Information

70

60

50

40

30

20

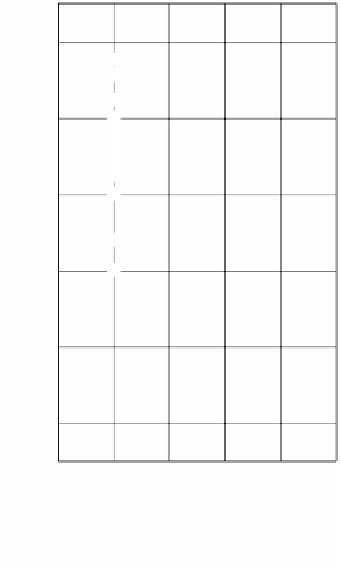

Type of recuperator

FIGURE 4.12

Types of recuperator and its heat recovery rate.

higher than 1250˚C. The value of 100 ppm NO

x

can be passed without problems at

a preheated air temperature well over 1000˚C and at a furnace temperature higher

than 1300˚C.

The change of driving mechanism from a pusher-type furnace to a walking-

beam-type began in 1967. Recently, a multiple-zone-type walking beam furnace has

become predominant. Technical measures to counter skid marks have not been solved

yet. Various counter-measures have been worked out, such as shifting of the skid

beam, heating method for aiming at the skid contacting portions by burners with a

long head that project out from the noses standing up through the furnace hearth

and from the furnace sidewall, adoption of gate-type posts, adoption of a taller skid-

height, and moderate cooling of skids. However, no effective countermeasure has

been found to date.

The applied HiTAC burner uses technologies of blowing air at a high velocity

to achieve homogeneous combustion entirely inside the furnace. Therefore, it is

expected that the gas, which was stagnating in all methods so far, will be able to

flow to the surroundings of the skid supports to where the gas did not diffuse. By

this effect, it is also expected that homogeneity of ambient atmospheric temperatures

in the lower part of the furnace can be improved, resulting in a decrease of skid marks.

Search WWH ::

Custom Search