Environmental Engineering Reference

In-Depth Information

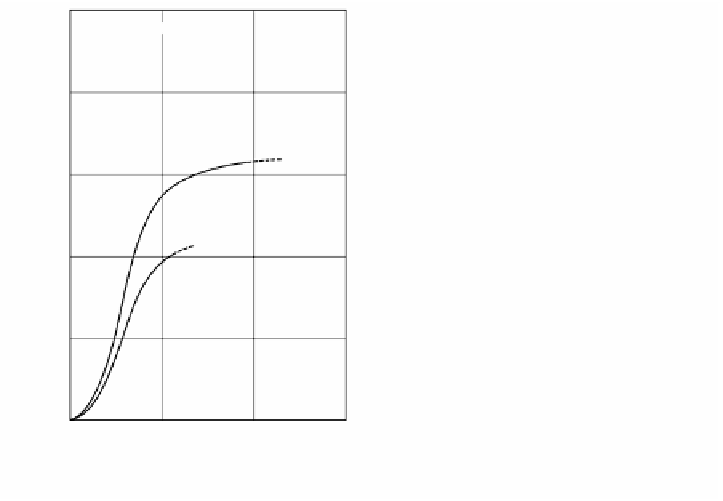

0.12

Two-dimensional Air Flow

Two-dimensional Air Flow

T =1280K

T =1280K

Yw =0.0008

0.10

0.02

a=40000s

-1

a=1300s

-1

1950K

0.08

a=24000s

-1

a=640s

-1

0.06

1550K

0.01

0.04

a=200s

-1

a=6900s

-1

0.02

1280K

0

0

1000

1500

2000

2500

1000

1500

2000

2500

Surface temperature, K

Surface temperature, K

(a)

(b)

FIGURE 2.135

Influence of the surface temperature on the combustion rate of a solid carbon

in high temperature airflow. The parameter is velocity gradient; (a) for the velocity gradient

at 1300 s

-1

or lower and (b) for the velocity gradient at 6900 s

-1

or higher.

result of thermal expansion reduces the mass flow rate of oxygen transported to the

surface of the carbon when the velocity gradient is kept at the same level.

Analytical study on the influence of the concentration of the oxygen in a high

temperature oxidizing agent on the combustion rate was also conducted. It revealed

that a combustion rate almost equivalent to that in room temperature airflow was

obtained even if the concentration was reduced to the mass rate of approximately

0.085. The test on the formation of a CO flame showed that the combustion rate

may be reduced by half depending on the surface temperature with the velocity

gradient set at about 1000 s

-1

or lower.

REFERENCES

1.

T. Hirano.

Combustion Science

, p. 31. Kaibundo, 1998 (in Japanese).

2.

K. Ito et al.

Trans. of JSME, ser. B

, 56:3508, 1998 (in Japanese).

3.

J. Kojima, Y. Ikeda, and T. Nakasima.

36th Japan Symposium on Combustion

, p. 560,

1998 (in Japanese).

4.

R. Weber et al.

Proceedings of 2nd International Seminar on High Temperature

Combustion in Industrial Furnace

, Stockholm, 2000.

5.

S. Mochida, T. Hasegawa, and R. Tanaka.

AFRC Fall Int. Symp.

, 1993.

6.

A. Sobiesiak, S. Rahbar, and H. A. Becker.

Combust. Flame

, 115:93, 1998.

7.

E. W. Grandmaison et al.

Combust. Flame

, 114:381, 1998.

8.

L. Yimer and B. H. A.

Can. J. Chem. Eng.

, 74:840, 1996.

Search WWH ::

Custom Search