Environmental Engineering Reference

In-Depth Information

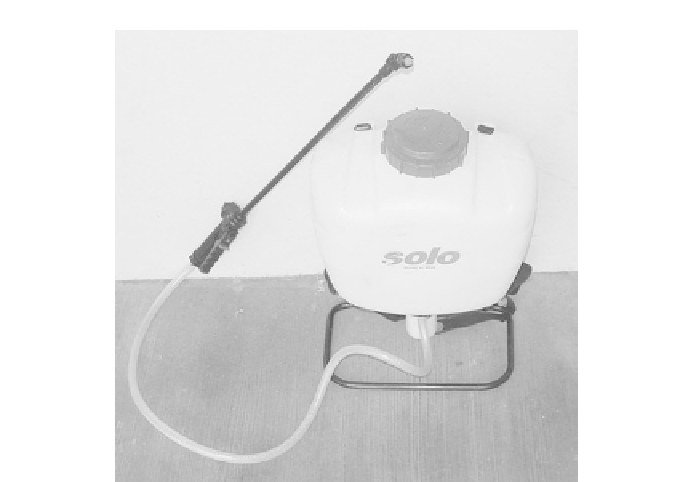

Fig. 11.5. Hand sprayers are used on small or hard-to-reach areas and usually have

only one nozzle.

(i) a hopper to hold the pesticide; (ii) a mechanical agitator at the base of

the hopper to provide a uniform and continuous feed; and (iii) some type

of metering device, usually a slit gate, to regulate the flow of granules.

Drop spreaders, also called gravity spreaders, apply coarse, uni-

formly sized dry particles to soil and sometimes foliage. An adjustable

sliding gate opens the outlet holes, and the granules flow out by gravity

feed. A revolving agitator is activated when the spreader is in motion to

ensure uniform dispensing. Drop spreaders are light and relatively sim-

ple and are generally more precise and deliver a better pattern than

rotary spreaders. Because the granules drop straight down, chemical

drift is minimal, control is good and the chance of applying pesticide to

non-target areas is small. Because the edge of a drop-spreader pattern is

sharp, any steering error will cause skips or overlaps. Application in

crossing directions usually helps to achieve better coverage, but com-

pletely uniform application is difficult to achieve with a drop spreader.

Rotary spreaders, both power- and hand-driven, distribute granules

to the front and sides of the spreader by means of a spinning disc or fan.

Most rotary spreaders produce a belt width of 2-3 m, so they cover an

area faster than drop spreaders. The rotary spreaders are usually easier to

push than drop spreaders but are less precise in uniformity and distri-

bution. In addition they are more sensitive to ground speed, physical

characteristics of the granules and environmental factors such as wind.