Civil Engineering Reference

In-Depth Information

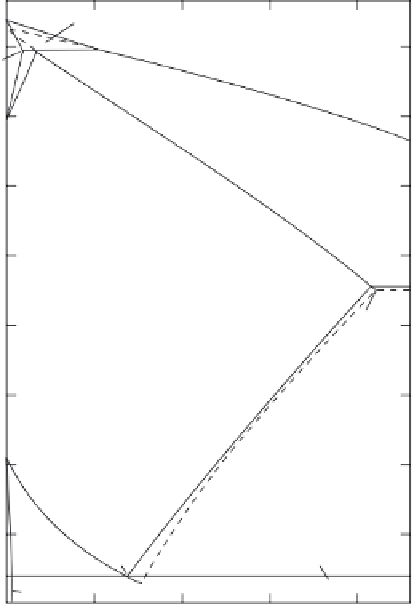

microstructure of steel is inherently heterogeneous, generally consisting of

grains (or 'phases', considered to be homogeneous in physiochemical

nature), dislocations, GBs, precipitates, and lattice defects. Figure 5.1 pres-

ents a portion of the equilibrium phase diagram of the Fe-C system under

atmospheric pressure (Chipman, 1972), which illustrates the thermodynam-

ics of three main phases in carbon steel, i.e., autensite (

), and

cementite (Fe

3

C), as a function of temperature and C content. Note that

equilibrium phases tend to form when there is suffi cient time to allow dif-

fusion of atoms and molecules. In many cases, the processing of steel may

include quenching or application of mechanical stress, which leads to the

formation of non-equilibrium phases such as martensite (

γ

), ferrite (

α

). For steels with

a signifi cant amount of alloying elements (e.g., stainelss steels), their micro-

structure may include many phases other than

α

′

γ

,

α

, and

α

′

(Lo

et al.

, 2009).

1527°

1538°

L +

δ

1495°

L (Liquid)

1500

0.53

0.09

δ

0.17

1400

1394°

L +

γ

1300

1200

γ

(Austenite)

1154°

1148°

2

.

08

2

.

11

110 0

1000

911.5°

900

γ

+ C

γ

800

+ Fe

3

C

α

+

γ

0.68

769°

α

+ C

738°

α

0.77

727°

700

0

0.5

1.0

1.5

2.0

2.3

Carbon (wt%)

5.1

Portion of the phase diagram Fe-C relevant to carbon steel.

Metastable

-range and system Fe-Fe

3

C shown by dashed lines.

Curie temperature dotted (adopted from Chipman, 1972).

With

kind

permission

from

Springer

Science

and

Business

Media.

γ

Search WWH ::

Custom Search