Civil Engineering Reference

In-Depth Information

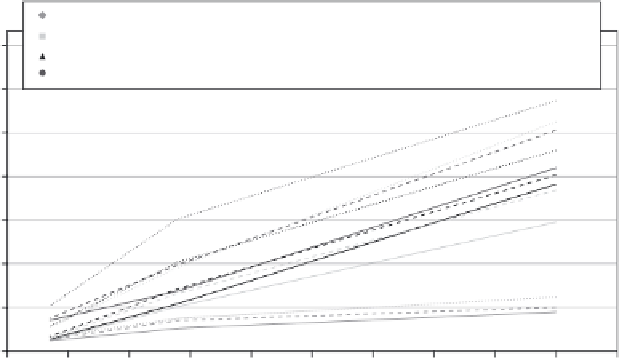

HPSCC,400

HPSCC,400,MS10%

HPSCC,400,NS

2%

HPSCC,400,NS

2%MS10%

HPSCC,450

HPSCC,450,MS10%

HPSCC,450,NS

2%

HPSCC,450,NS

2%MS10%

HPSCC,500

HPSCC,500,MS10%

HPSCC,500,NS

2%

HPSCC,500,NS

2%MS10%

720

620

520

420

320

220

120

20

0

10

20

30

40

50

60

70

80

90

100

Time (days)

3.3

Resistivity versus time for different mixtures (Nazari and Riahi,

2011b).

between nanoparticles existing in higher concentration, so limiting the for-

mation and growth of Ca(OH)

2

crystals due to space limitations. In this

situation, the ratio of crystals to C-S-H gel is reduced and the shrinkage

and creep of the cement matrix tend to increase. In consequence, the pore

structure of the cement matrix is relatively more coarse (Zhang and Li,

2011).

3.2.3 Control of calcium leaching

High durability concrete requires the reduction of calcium leaching. This

degradation process consists of a progressive dissolution of the cement

paste caused by the migration of calcium atoms to the aggressive solution.

Cement paste phases have different rates of degradation. While Portlandite

dissolves completely in an aggressive solution, C-S-H gel undergoes only a

slight increase in porosity (Carde

et al.

, 1996; Kamali

et al.

, 2003; Haga

et al.

, 2005; Gaitero

et al.

, 2012). Calcium leaching is responsible for an

increase in concrete porosity and consequently in increased permeability.

This allows water and other aggressive elements to enter the concrete which

causes carbonation and corrosion problems. Gaitero

et al.

(2008) studied

the infl uence of silica nanoparticles on the reduction of calcium leaching.

Concrete mixtures containing 6% (by weight of cement) of four different

types of commercial silica nanoparticles (Table 3.1) were used.

Figure 3.4 shows that the addition of silica nanoparticles to the cement

paste favors the growth of silicate chains. This is advantageous as longer

Search WWH ::

Custom Search