Civil Engineering Reference

In-Depth Information

family, polycrystalline and amorphous, but also not forgetting the semicon-

ductor PVs that are manufactured from compound materials and the new

and promising third generation developments. This section gives an over-

view of how and why the technology moved from the fi rst to the second

generation, and how it is hoped that the best of both can be used to provide

a third generation that might solve all previously acknowledged issues.

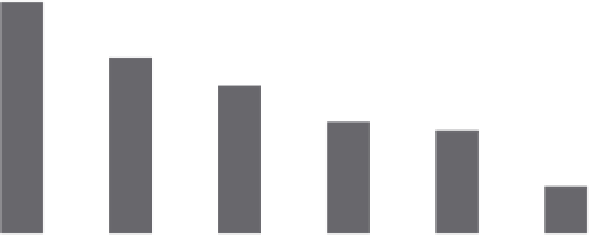

Figure 12.4 outlines the effi ciency levels of some of the fi rst, second and

third generation PVs, recorded in 2010 (Saari, 2010).

The following sections summarize where the technologies are now but

also question how they got to this point and the historical steps that were

taken to arrive at today's technology, before providing a glimpse of where

it could go in the future.

12.4.1 First generation

The fi rst generation had one simple task, with no limitations, which was split

into two steps:

1. Absorb light energy so positive and negative charges can be

generated.

2.

Create a potential difference by separating the positive and negative

charges.

This generation of solar cells is commonly known to have, on the positive

side, high effi ciency, but on the fl ip side it also has a higher cost, to be

expected with any new technology. It is estimated that the maximum theo-

retical effi ciency that these single junction silicon cells could hope to reach

is approximately 33%, limited only by thermodynamics (Shockley and

Queisser, 1961). To date, fi rst generation PVs account for the largest market

25

19

Efficiency (%)

16

12

11

5

Crystalline

silicon

Thin film -

CIGS

Thin film -

CdTe

Thin film -

aSi

Dye

sensitized

Organic PV

12.4

Energy levels achieved by PVs in 2010 (Saari, 2010).

Search WWH ::

Custom Search